A Complete Overview of Industrial Remote Controls: Features, Benefits, and Applications

A Complete Overview of Industrial Remote Controls: Features, Benefits, and Applications

Industrial remote controls have become essential tools in modern industries, allowing operators to manage large machinery safely and efficiently from a distance. KCICRANES Machinery, based in Xinxiang, Henan, China, specializes in high-quality industrial remote controls and a wide range of crane products that enhance productivity in heavy-duty operations. This guide will provide an in-depth look at industrial remote controls, covering their key features, advantages, applications, and factors when choosing the right remote control for your operations.

What Are Industrial Remote Controls?

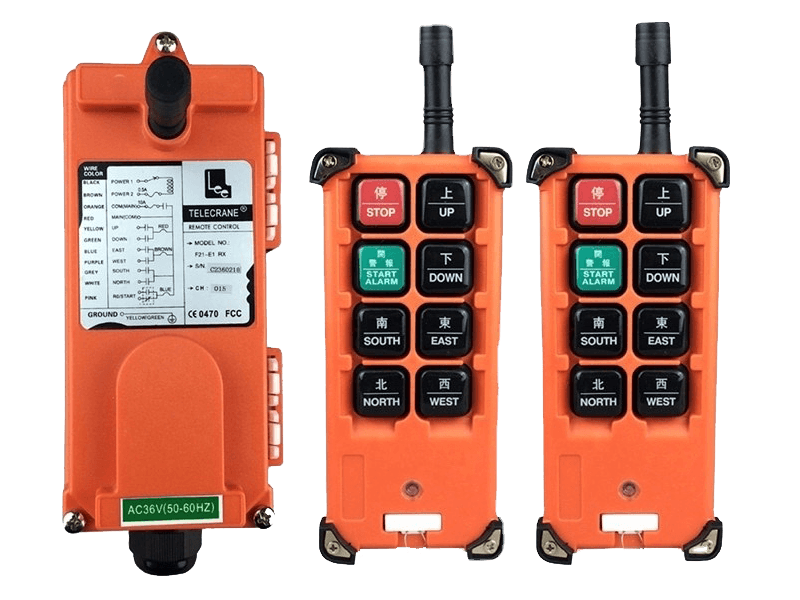

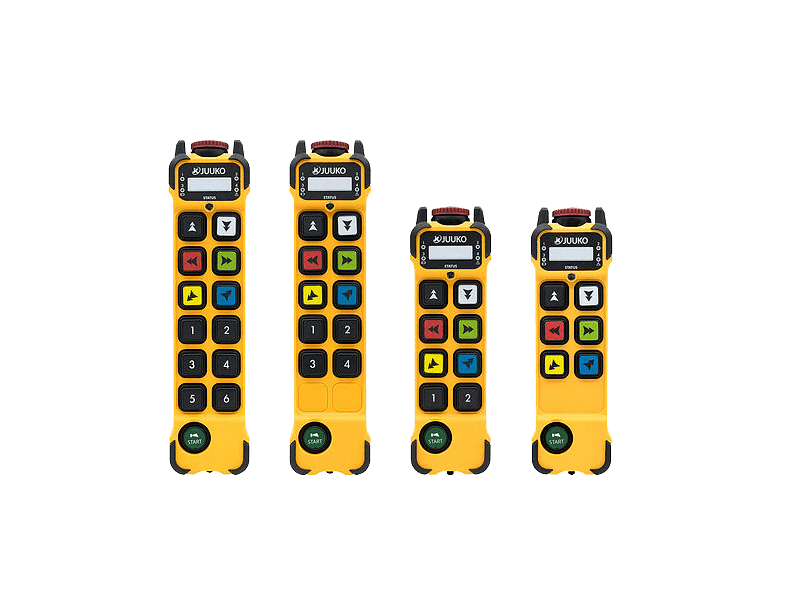

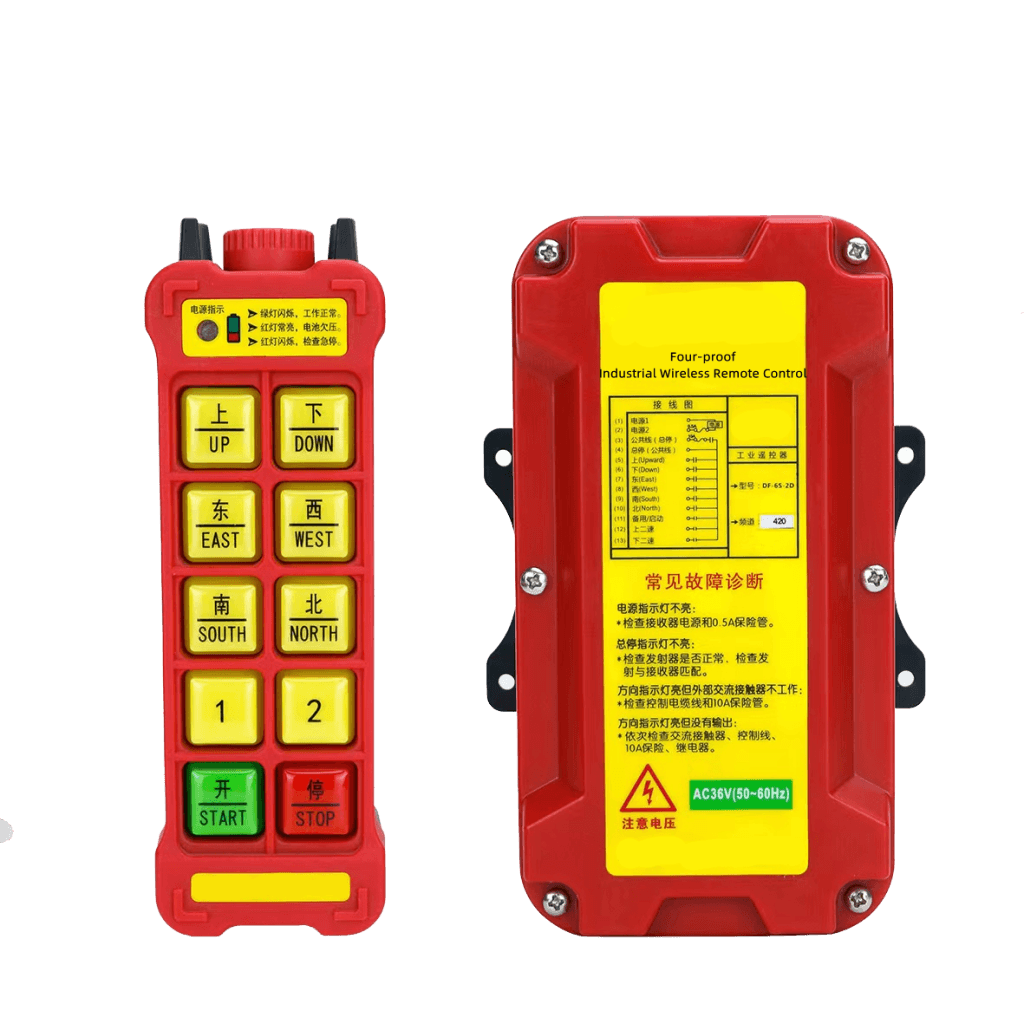

Industrial remote controls are wireless devices designed to control and operate heavy equipment in industries like construction, logistics, and manufacturing. These remote controls use radio frequency or infrared technology to allow operators to manage machinery without physical contact. They are especially useful in handling cranes, winches, hoists, and other equipment that require precision and safety in hazardous or challenging environments.

At KCICRANES Machinery, our industrial remote controls are built to withstand the demands of tough work environments. Designed with durability in mind, they are dustproof, waterproof, and highly resistant to wear and tear, ensuring long-lasting performance and safety.

Key Features of Industrial Remote Controls

- Durability and Protection: Industrial remote controls from KCICRANES are constructed to resist dust and water, making them ideal for rough environments where traditional wired controls would struggle. They are built with robust materials that withstand drops, shocks, and frequent use.

- Precision and Control: These controls provide precise operation, allowing workers to handle equipment with high accuracy. This is crucial when positioning heavy loads in limited spaces, as even slight errors can be costly or dangerous.

- Safety Features: Safety is paramount in heavy industries, and industrial remote controls come with various safety features, including emergency stop buttons, overload protection, and frequency hopping technology to prevent interference with other devices.

- Long-Range Operation: The remote controls have a significant operating range, enabling operators to manage machinery from a safe distance. This is especially important in hazardous environments where proximity to the equipment could pose risks.

- Ease of Use: Equipped with ergonomic designs, industrial remote controls are easy to use, even for extended periods. The buttons are large, responsive, and easy to understand, minimizing the chances of operational errors.

Applications of Industrial Remote Controls

Industrial remote controls have a broad range of applications across various sectors. Some of the primary uses include:

- Cranes and Hoists: In construction and manufacturing, cranes are essential for moving heavy loads. Remote controls allow operators to position these loads precisely and from a safe distance, making operations more efficient and reducing risks.

- Winches: Remote controls are also widely used with winches to lift and lower heavy objects. By allowing control from a distance, remote systems ensure safer handling and prevent workers from getting too close to potentially hazardous areas.

- Automated Storage and Retrieval Systems: In large warehouses and distribution centers, industrial remote controls help operators manage automated storage and retrieval systems, improving productivity and inventory management.

- Material Handling Equipment: In logistics and manufacturing environments, remote controls are used to operate forklifts, transfer cars, and other material handling equipment, making it easier to transport heavy items safely.

- Mining and Heavy Industry: In mines and other harsh environments, industrial remote controls allow workers to operate machinery safely, often from within a protected enclosure. This is crucial for preventing accidents in areas where falling debris or hazardous materials pose a risk.

Benefits of Using Industrial Remote Controls

The use of industrial remote controls brings several advantages to businesses and operators, such as:

- Enhanced Safety: By enabling operators to control machinery from a safe distance, remote controls help prevent workplace accidents, particularly in environments where heavy loads or dangerous materials are involved.

- Increased Efficiency and Productivity: With remote operation, workers can handle multiple tasks without needing to be near the machinery, reducing idle time and increasing the speed of operations.

- Reduced Maintenance Costs: Wired control systems are prone to wear and tear, especially in harsh industrial environments. Remote controls eliminate the need for long cables, reducing maintenance costs associated with damaged wires and connectors.

- Improved Ergonomics: Industrial remote controls are ergonomically designed, minimizing operator fatigue and making it easier to handle machinery for extended periods. This contributes to a more comfortable work experience and better overall productivity.

- Flexibility in Operations: Remote controls allow companies to adapt to different tasks and environments. Operators can handle equipment in varying conditions without extensive setup, making remote controls versatile tools across industries.

Factors to Consider When Choosing Industrial Remote Controls

When selecting an industrial remote control system, it’s essential to consider specific factors that will impact its performance and suitability for your operation:

- Range and Signal Strength: Ensure that the remote control has a range that meets the needs of your workspace. High-frequency interference in industrial settings can sometimes disrupt signal transmission, so look for remote controls with robust signal strength.

- Battery Life and Power: Choose a remote control with a long battery life or easy-to-replace batteries to avoid downtime. Many systems also offer low-battery alerts to inform operators when it’s time for a recharge or replacement.

- Compatibility with Equipment: Verify that the remote control system is compatible with the specific machinery you are using. Some systems are designed to work with a range of equipment, while others are more specialized.

- Environment Requirements: Consider whether the environment is dusty, wet, or exposed to extreme temperatures. Ensure the remote control is rated for the conditions it will be used in, such as IP65 or higher for dust and water resistance.

- Safety Standards Compliance: Select a remote control system that complies with relevant safety standards and certifications to meet industry regulations and ensure the safety of your operations.

About KCICRANES Machinery

KCICRANES Machinery is a leading manufacturer of cranes, crane accessories, and remote control systems based in Xinxiang, Henan, China. Our extensive product line includes gantry cranes, bridge cranes, crane end beams, crane wheels, transfer cars, and conductor bars. We focus on delivering durable, high-quality equipment that meets the rigorous demands of industrial operations. With our expertise in lifting and material handling solutions, KCICRANES Machinery supports businesses worldwide in enhancing safety, efficiency, and productivity.

For more information on our industrial remote controls and other crane solutions, reach out to KCICRANES Machinery. Our team is ready to help you find the perfect solution for your operational needs.

About KCICRANES Machinery

KCICRANES Machinery is a leading manufacturer of cranes and crane accessories. Our dedication to quality and innovation ensures that our products meet your lifting needs efficiently and safely.

Industrial cranes(overhead cranes, gantry cranes, jib cranes. etc) are complex machines with many parts, each critical for safe and efficient operation. At KCICRANES, we provide an extensive range of replacement parts, including:

1. Wire Rope Hoists

Wire rope hoists are essential components of many industrial cranes. They lift and lower loads with precision, but wear and tear can cause them to degrade over time. KCICRANES offers a variety of hoist replacements crafted with durability and strength to support safe and efficient operations.

2. End Trucks

End trucks carry the weight of the crane and allow it to move along its runway. When end trucks fail, it can halt crane movement entirely. Our end trucks are designed for long-lasting performance and fit seamlessly with different crane types.

3. Winch Trolleys

Also called crane winches, electric winches, and crane trolleys.etc

4. Crane Controls

Control systems are the brain of your crane operations. Faulty controls can lead to erratic movements and safety issues. We offer control system replacements, from handheld remotes to intricate PLC systems, to keep your crane operating smoothly and safely.

5. Power Rotating Blocks and Transfer Cars

Used primarily in transfer applications, power rotating blocks and transfer cars allow cranes to handle and rotate heavy loads. When these components show signs of wear, replacing them can prevent accidents and enhance handling efficiency.

Maintaining Your Industrial Crane: Key Tips

Regular maintenance and timely replacement of parts are vital for any industrial crane. Here are some tips to help extend the life of your equipment:

- Conduct Regular Inspections: Check for wear on hoists, cables, and structural components. Early detection of issues can prevent costly repairs.

- Keep Spare Parts Handy: Having essential spare parts on hand reduces downtime in case of unexpected failures.

- Lubricate Moving Parts: Proper lubrication helps reduce friction and wear on moving parts, especially in high-use environments.

- Stay Compliant with Regulations: Regularly inspect and replace parts as per industry standards to ensure safety and compliance.

FAQs: Replacement and Spare Parts for Industrial Cranes

1. How do I know when a part needs replacing?

Signs like unusual noises, reduced performance, and visible wear are common indicators. Regular inspections can help identify parts that need replacing before they fail.

2. Are KCICRANES parts compatible with all industrial cranes?

Our parts are designed to fit a wide range of crane models. Contact our team to confirm compatibility with your specific crane type.

3. What types of industries do you serve?

KCICRANES serves industries ranging from manufacturing and construction to logistics and shipyards. We tailor our parts to meet the demands of each sector.

4. How quickly can I receive replacement parts from KCICRANES?

We keep many of our parts in stock, ready to ship. Shipping times will depend on your location, but we strive to ensure quick delivery.

If you need any other crane kits, welcome to send a free inquiry.Email:info@kcicranes.com

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com