KCICRANES-Professional Crane Kits Supplier

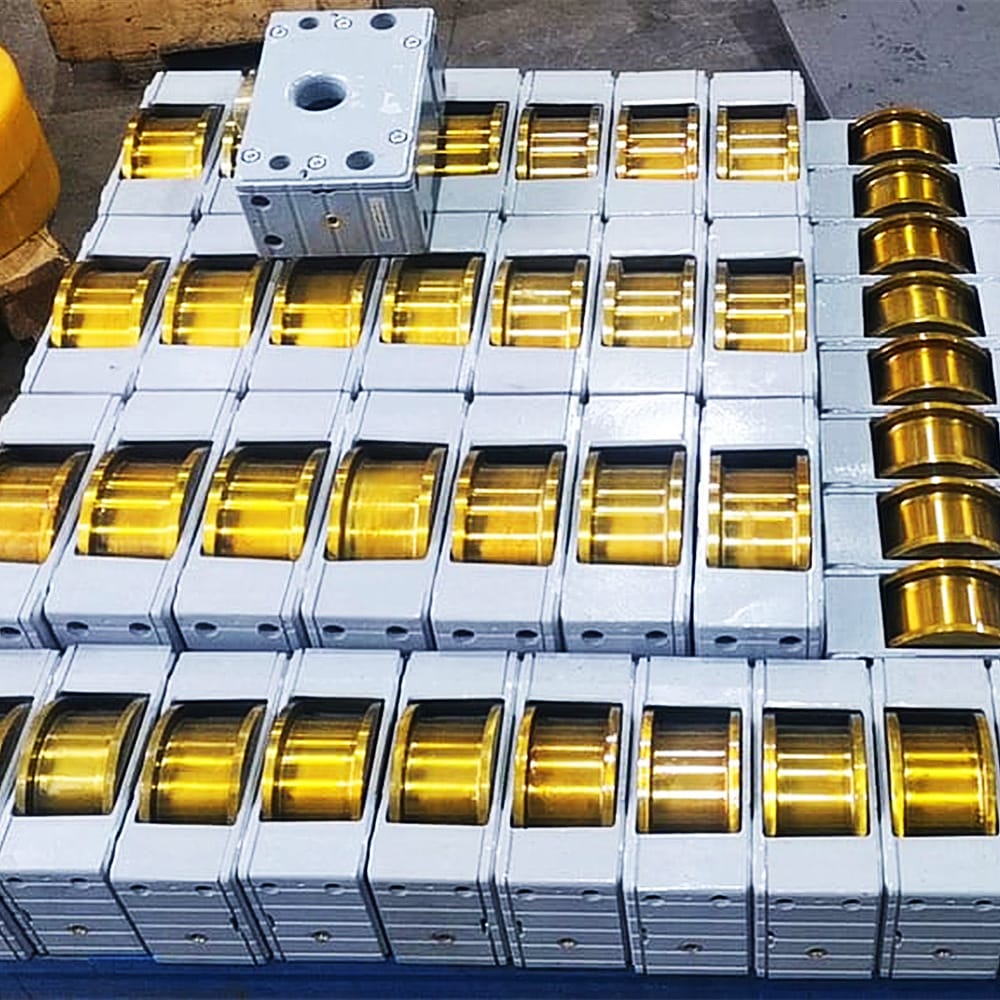

What Is a Forged Crane Wheel Assembly?

The term “forged crane wheel assembly” might sound technical, but it’s essentially the powerhouse behind industrial cranes. These assemblies ensure the smooth movement of cranes, even under heavy loads, while withstanding harsh environments. Whether it’s gantry cranes, overhead cranes, or transfer trolleys, these wheels are the unsung heroes that keep everything running seamlessly. At KCICRANES Machinery, a leading crane and crane kit manufacturer in China, we specialize in designing and producing high-quality forged crane wheel assemblies tailored to your needs.

Importance in Industrial Applications

Forged crane wheels are critical in the manufacturing, mining, and logistics industries. These wheels handle intense pressure and ensure cranes operate efficiently during lifting and transportation tasks. With their incredible strength and precision, they’ve become a staple in heavy-duty industrial operations.

Contact us at info@kcicranes.com for more details!

Difference Between Forged and Cast Wheels

So, what makes forged wheels stand out? Forged wheels are crafted by compressing heated metal into shape, making them denser and more robust than cast wheels, which are made by pouring molten metal into molds. The forging process eliminates porosity, enhancing the wheel’s durability and resistance to stress. That’s why forged wheels are preferred for high-stress applications like cranes.

Key Features of Forged Crane Wheels

These wheels are a testament to engineering excellence. Features like a tough exterior, wear resistance, and superior load capacity make them perfect for demanding environments. Plus, they can be customized to suit different crane types, ensuring optimal performance every time.

Wheel Structure and Materials

Forged crane wheels typically feature a solid steel construction, ensuring maximum durability. High-grade alloys are often used to improve strength and resist deformation. The design of the wheel, from its tread to its flange, is meticulously engineered for smooth operations.

Bearings and Axles

Bearings and axles are critical for wheel functionality. Precision-engineered bearings reduce friction, while robust axles support the wheel and maintain alignment during operation. At KCICRANES Machinery, we use the highest-quality components for our assemblies.

Lubrication Systems

Proper lubrication is vital to reduce wear and tear. Advanced systems ensure the smooth operation of the wheels and extend their lifespan, even under challenging conditions.

Enhanced Durability

Forged crane wheels are built to last. The forging process creates a dense structure that can withstand intense pressure, ensuring your crane operates flawlessly for years.

Load-Bearing Capacity

One standout feature of forged wheels is their remarkable load-bearing capacity. They can handle extreme weights without compromising performance, making them ideal for heavy-duty tasks.

Resistance to Wear and Tear

Daily use in industrial environments takes a toll on equipment. Fortunately, forged crane wheels are highly resistant to wear, reducing downtime and maintenance costs.

Industries That Rely on Forged Wheels

You’ll find forged crane wheels in industries like construction, steel production, and shipbuilding. Their strength and reliability make them indispensable in these sectors.

Use in Overhead and Gantry Cranes

Overhead and gantry cranes rely heavily on forged wheel assemblies to move materials with precision. Their robust design ensures seamless operations even in high-pressure situations.

Proper Installation

Want to maximize the lifespan of your crane wheels? It starts with proper installation. Misalignment or improper assembly can lead to premature wear, so always follow manufacturer guidelines.

Routine Inspection Practices

Regular inspections help identify issues like cracks or wear before they become major problems. A simple visual check can go a long way in ensuring safety and efficiency.

Common Maintenance Mistakes to Avoid

Avoid overloading the crane, neglecting lubrication, or ignoring strange noises during operation. These mistakes can drastically reduce the lifespan of your crane wheels.

Expertise and Custom Solutions

At KCICRANES Machinery, we’re more than just manufacturers; we’re your partners in lifting solutions. From custom designs to premium materials, we provide crane wheel assemblies that meet your specific needs.

Contact Us

Need help with your crane wheel assembly? Reach out to KCICRANES Machinery at info@kcicranes.com. We’re here to provide expert advice and top-notch products!

Wrapping Up the Essentials

A forged crane wheel assembly isn’t just another component; it’s the backbone of reliable crane operations. With superior durability, impressive load capacity, and minimal maintenance needs, these wheels are an investment in efficiency and safety. If you’re in the market for the best crane wheels, look no further than KCICRANES Machinery. Reach out today and let us help you lift your business to new heights!

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com