KCICRANES-Professional Crane Kits Supplier

When we think of a bridge crane, our minds often picture the massive steel structure lifting tons of materials in an industrial setting. However, behind that incredible performance lies one crucial component that ensures smooth operation—bridge crane wheels. These often-overlooked parts play a significant role in keeping the crane moving efficiently along its track, bearing heavy loads, and maintaining precision. Whether you are in the construction, manufacturing, or logistics industry, understanding the importance of high-quality bridge crane wheels can help you improve crane performance, reduce maintenance costs, and avoid downtime.

At KCICRANES Machinery, we specialize in designing and producing top-notch bridge crane wheels, along with a wide range of industrial crane components. Let’s dive into why bridge crane wheels are essential and how investing in quality ones can make a huge difference in your crane operations.

We specialize in high-quality crane solutions at KCICRANES Machinery, a leading crane and crane parts manufacturer in China. For inquiries, contact us at info@kcicranes.com.

What Are Bridge Crane Wheels?

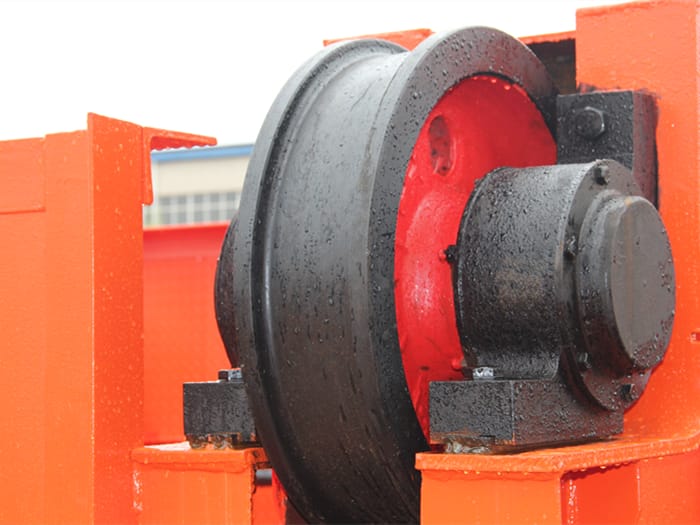

Bridge crane wheels are the wheels installed on the end carriages of bridge cranes, which enable the crane to move along a fixed track or runway. They are designed to handle the weight of the crane and its load, ensuring smooth, precise movement. These wheels play a critical role in the crane’s mobility and stability.

Typically, bridge crane wheels are made from strong, durable materials like cast steel, alloy steel, or other high-quality alloys capable of withstanding heavy-duty stress. These wheels are built to last, operating under constant load, friction, and sometimes even harsh environmental conditions.

Why Are Bridge Crane Wheels So Important?

1. Ensuring Smooth and Stable Movement

The primary function of crane wheels is to allow for smooth and stable movement of the crane across its track. This is crucial, especially when handling heavy loads. If the wheels are poorly designed or worn down, the crane might experience jerky or unstable movements, leading to inefficient operations, potential accidents, and material damage. High-quality wheels ensure that your crane moves as intended, with minimal friction and maximum stability.

2. Load Distribution and Durability

Crane wheels carry the weight of the crane itself, along with any loads it may be lifting. The wheels must be strong enough to distribute this weight evenly across the track, ensuring that no part of the crane is subjected to excessive stress. Durable bridge crane wheels are designed to withstand constant wear and tear, minimizing the need for frequent replacements. This makes them a long-term investment in the efficiency and longevity of your crane system.

3. Reducing Maintenance Costs

When you invest in top-quality bridge crane wheels, you reduce the risk of damage or wear that could result in costly repairs or downtime. Well-maintained, durable wheels ensure that your crane operates smoothly, preventing unnecessary repairs and extending the lifespan of the entire system. This leads to lower maintenance costs over time and fewer disruptions to your operations.

4. Safety Considerations

The stability of the crane’s movement is directly related to safety. If the wheels fail to function correctly, the crane could become unstable, especially when handling large or heavy loads. High-quality bridge crane wheels reduce the risk of such accidents, ensuring that the crane remains operational and safe for workers and equipment. Proper wheel maintenance is a vital part of any safety protocol in industrial settings.

Different Types of Bridge Crane Wheels

Not all bridge crane wheels are the same—different industries, crane capacities, and operational needs require various wheel types. Let’s take a look at the most common types:

1. Standard Crane Wheels

These are the most commonly used wheels for general-purpose bridge cranes. They are designed to handle medium load capacities and are typically made of cast steel. Standard wheels are a reliable option for most standard crane operations.

2. Heavy-Duty Crane Wheels

For industries that require higher load capacities—such as heavy manufacturing, mining, or construction—heavy-duty bridge crane wheels are necessary. These wheels are built with thicker walls and higher-grade materials, enabling them to carry heavier loads and withstand more stress. They also tend to be more resistant to wear and damage.

3. Corrosion-Resistant Crane Wheels

In environments where corrosion is a concern, such as chemical plants or outdoor construction sites, corrosion-resistant bridge crane wheels are a must. These wheels are typically coated or made from specialized alloys that can resist rust and other forms of corrosion, ensuring longevity and consistent performance in harsh environments.

4. Custom Crane Wheels

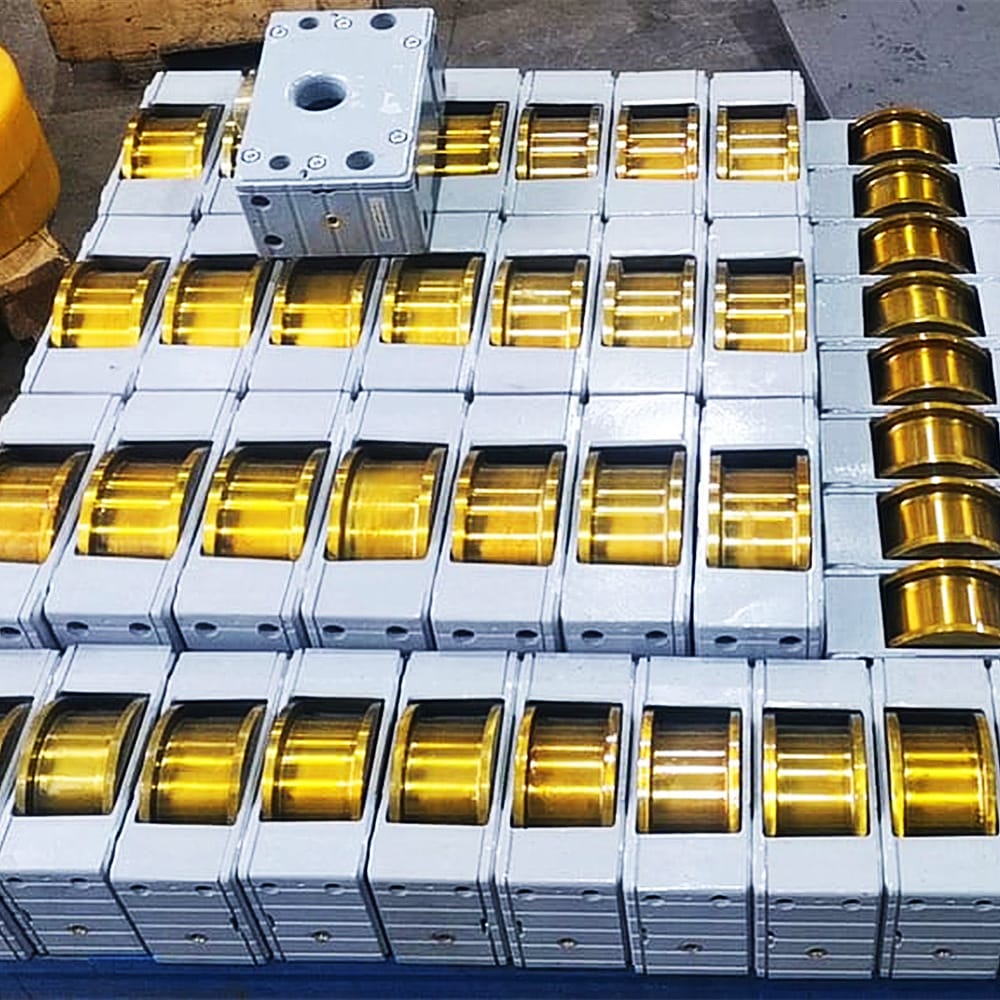

Sometimes, a one-size-fits-all solution simply won’t do. For specific crane designs or unique operational needs, custom bridge crane wheels are the perfect solution. At KCICRANES, we offer fully customizable wheels tailored to meet the precise requirements of your crane system, including size, load capacity, and environmental considerations.

Why Choose KCICRANES for Your Bridge Crane Wheels?

As a leading manufacturer of industrial cranes and crane components in China, KCICRANES Machinery stands out for its dedication to quality, customization, and customer satisfaction. Here’s why we are the go-to choice for bridge crane wheels:

1. Expert Manufacturing

At KCICRANES, we leverage years of expertise and advanced technology to design and manufacture high-quality bridge crane wheels. Our team of engineers ensures that each wheel is built to exact specifications, guaranteeing smooth performance and long-lasting durability.

2. Customized Solutions

We understand that every industrial setting is different. That’s why we offer customized bridge crane wheels that are tailored to your specific needs. Whether you need wheels for a lightweight crane or a heavy-duty system, we can provide the perfect solution to fit your requirements.

3. Comprehensive Product Range

KCICRANES isn’t just about bridge crane wheels—we offer a wide range of crane components, including overhead cranes, portable gantry cranes, jib cranes, crane trolleys, and more. With all of your crane needs covered under one roof, we make the procurement process simpler and more efficient for you.

4. Global Reach and Reliable Support

We serve clients around the world, providing timely delivery and ongoing support. Our customer service team is always ready to assist you with any questions or concerns, ensuring that your experience with KCICRANES is smooth from start to finish.

Applications of KCICRANES Crane Wheels

Bridge crane wheels are used in a variety of industries, including:

- Manufacturing: For moving heavy materials or products along assembly lines.

- Construction: In construction sites for lifting and moving heavy construction materials.

- Logistics and Warehousing: For transporting goods and containers in warehouses, ports, and distribution centers.

- Shipping: For lifting and moving heavy loads on dockside cranes.

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

When it comes to crane wheels, quality is key. The right wheels can make the difference between smooth, efficient operations and costly, disruptive downtime. By choosing KCICRANES Machinery for your cranes and crane components, you ensure that your crane system operates at peak performance, with safety and durability guaranteed.

For a free inquiry or more information on our products, don’t hesitate to contact us at info@kcicranes.com. Let KCICRANES be your trusted partner in enhancing your crane operations today!

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com