| Parameter | Range |

| Bucket Type | Hydraulic, Mechanical |

| Load Capacity | 1 ton, 5 tons, 10 tons, 20 tons,customizable |

| Opening Width | 500 mm, 800 mm, 1000 mm,1800mm,8000mm, customizable |

| Bucket Volume | 0.5 m³, 1 m³, 2 m³, 10 m³,20 m³,customizable |

| Weight | Ranges from 200 kg to 30 tons |

| Operating Temperature Range | -20°C to 50°C, with options for extreme conditions |

| Control Type | Manual, Remote, or Automatic |

Chain Block 10 Ton: The Ultimate Guide

At KCICRANES Machinery, we specialize in the design, manufacturing, and supply of high-quality crane bucket grabs for a wide variety of industrial applications. As a leading crane kits manufacturer in China, our primary focus is to provide reliable, durable, and efficient solutions that meet the demands of our global clientele. In this guide, we will delve deep into what a crane bucket grab is, its types, and how to choose the right solution for your project.

What is a Crane Bucket Grab?

A crane bucket grab, also known as a grab bucket, is an essential attachment for lifting and transporting loose materials. These materials can include sand, gravel, coal, grain, and other bulk items that require precision handling. The bucket grab operates by clamping around the material and lifting it securely, often used in ports, construction sites, and industrial environments. By enabling easy loading and unloading of materials, crane bucket grabs significantly increase operational efficiency and productivity.

Types of Crane Bucket Grabs

Different types of crane bucket grabs are suited for varying applications. At KCICRANES Machinery, we offer a range of bucket grab models designed to handle specific types of loads and operating conditions.

1. Mechanical Grab Buckets

Mechanical grab buckets are operated via the crane’s mechanical system and are typically used in environments where precise control of material handling is not as critical. These grabs are easy to maintain and highly durable, making them suitable for long-term use in industries like construction and mining.

- Single rope grabs: Best suited for environments where cranes with only one hoist drum are available.

- Double rope grabs: Used with cranes equipped with two hoist drums, allowing for enhanced stability and control.

- Four-rope grabs: Offer even greater stability and are often used for heavy-duty material handling in high-volume environments like ports.

2. Hydraulic Grab Buckets

Hydraulic grab buckets use hydraulic cylinders to operate the opening and closing of the bucket. These types are ideal for projects requiring precise control over the handling of materials. Hydraulic buckets are commonly used for lifting irregularly shaped materials or fragile loads.

- Two-jaw hydraulic grabs: These are suitable for materials such as scrap metal or rocks, where a strong clamping force is needed.

- Four-jaw hydraulic grabs: Typically used for finer, loose materials like sand or grain.

3. Clamshell Grab Buckets

Clamshell grab buckets are designed with a dual-sided, clam-like structure. These buckets are commonly used for dredging, excavation, and bulk material loading and unloading. Their superior gripping force makes them highly efficient in handling materials like coal, sand, and other granular substances. Clamshell grabs can be mechanical or hydraulic, depending on the needs of the application.

4. Orange Peel Grab Buckets

These specialized grabs are equipped with multiple arms resembling the segments of an orange peel. Orange peel grabs are perfect for handling irregular and bulky materials such as scrap metal and heavy industrial waste. Their multi-jaw design ensures that even the most difficult loads can be handled efficiently.

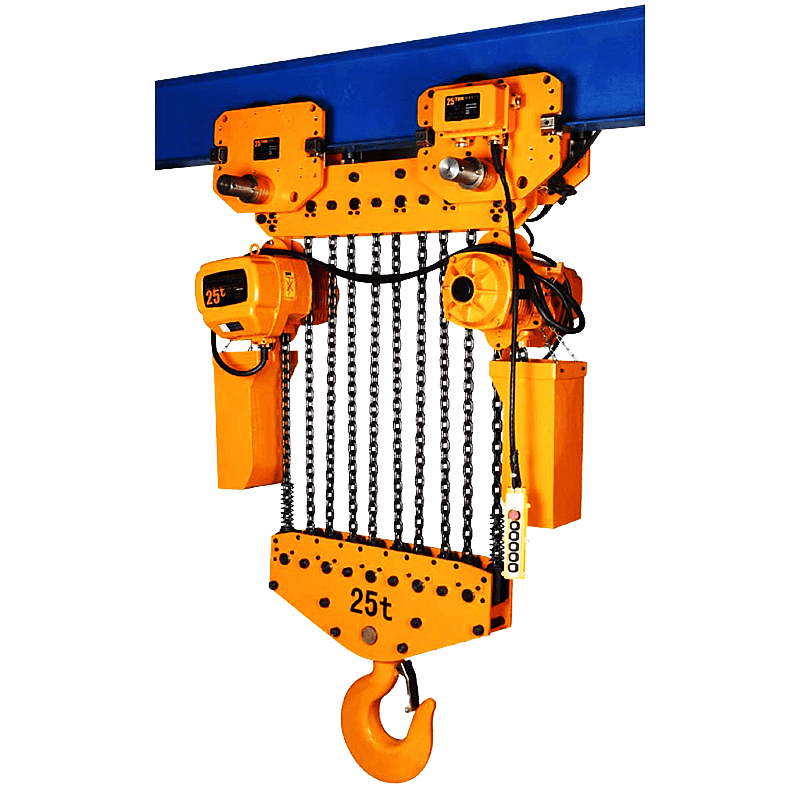

Key Features to Look for in a 10-Ton Chain Block

There’s more to a good chain block than just its lifting capacity. If you’re shopping around for a 10-ton chain block, here are some key features to consider:

Load Capacity and Safety Standards

First and foremost, always ensure the chain block complies with safety standards. Look for certifications such as ASME (American Society of Mechanical Engineers) or CE (Conformité Européenne) marking, which guarantee that the device meets specific safety and performance criteria.

Durability and Build Quality

A 10-ton chain block needs to be robust enough to handle extreme loads, so check the build quality. High-grade steel construction, corrosion resistance, and reinforced gears are all indicators of a well-made unit that will stand the test of time.

Ease of Operation

While power is critical, ease of use matters just as much. Look for a chain block with smooth gear operation, a lightweight design (as far as possible for its capacity), and ergonomic features like a comfortable hand chain grip.

Benefits of Using KCICRANES Crane Bucket Grabs

At KCICRANES Machinery, our crane bucket grabs are engineered for performance, reliability, and longevity. Here are several reasons why our grabs stand out in the market:

- Durability: Our bucket grabs are made from high-quality steel and built to withstand harsh environments, ensuring long service life.

- Customizable Designs: We offer tailor-made solutions to suit the specific requirements of your project. Whether you need a special capacity or a unique grab configuration, we can meet your needs.

- Advanced Technology: Our hydraulic grabs are equipped with state-of-the-art hydraulic systems, allowing for precision control and efficient material handling.

- Low Maintenance: Our mechanical grabs are designed for low-maintenance operation, reducing downtime and operational costs.

- Global Reach: With clients across the globe, we have a proven track record of delivering high-quality products on time, no matter where you are located.

Below are CRANE CLAWS,if you need any other crane kits,welcome to send a free inquiry.Email:info@kcicranes.com

At KCICRANES Machinery, we are committed to providing the best electric hoists on the market.

FAQs about 10-Ton Chain Blocks

What’s the difference between a chain block and a lever hoist? While both are lifting devices, a lever hoist uses a lever for operation, while a chain block uses a hand chain.

What is the maximum load for a 10-ton chain block? A 10-ton chain block can lift up to 20,000 pounds safely.

Can I use a 10-ton chain block for outdoor lifting? Yes, as long as the chain block is weather-resistant and properly maintained.

How often should I inspect my chain block? Regular inspections should be conducted before each use, and a thorough maintenance check every few months.

Are there electric versions of 10-ton chain blocks? Yes, many manufacturers offer electric chain blocks for faster and easier lifting.

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com