Comprehensive Guide to QD Trolley Cranes: Features, Applications, and Advantages

The QD Trolley Crane stands out as a high-performance solution in modern industries where material handling and load management are crucial. Built for efficient and reliable operations, QD Trolley Cranes are widely used across various industries, including manufacturing, warehousing, and logistics.We also have overhead cranes, gantry cranes,jib cranes,crane drums.etc

In this article, we’ll explore what makes QD Trolley Cranes unique, explore their main features, and outline their benefits in different industrial settings.

What is a QD Trolley Crane?

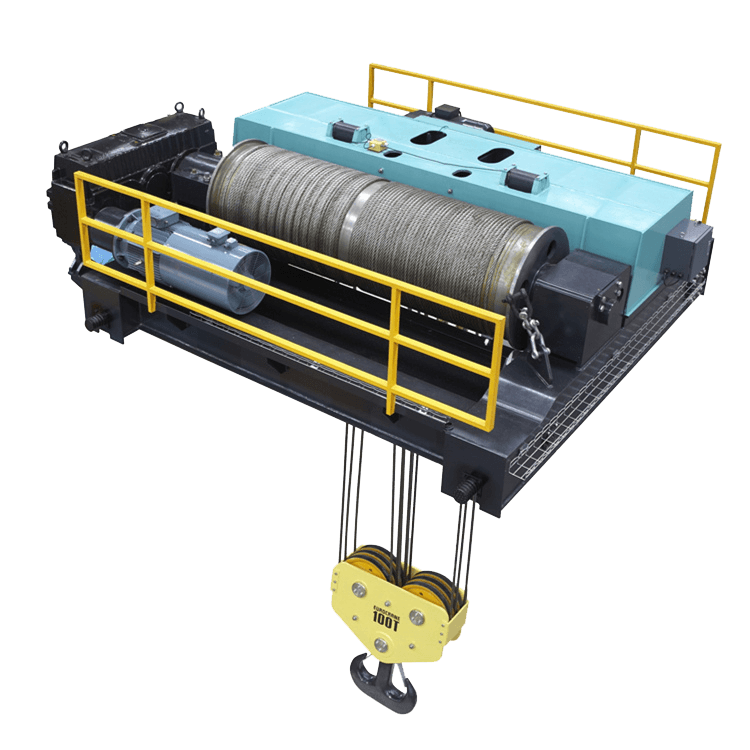

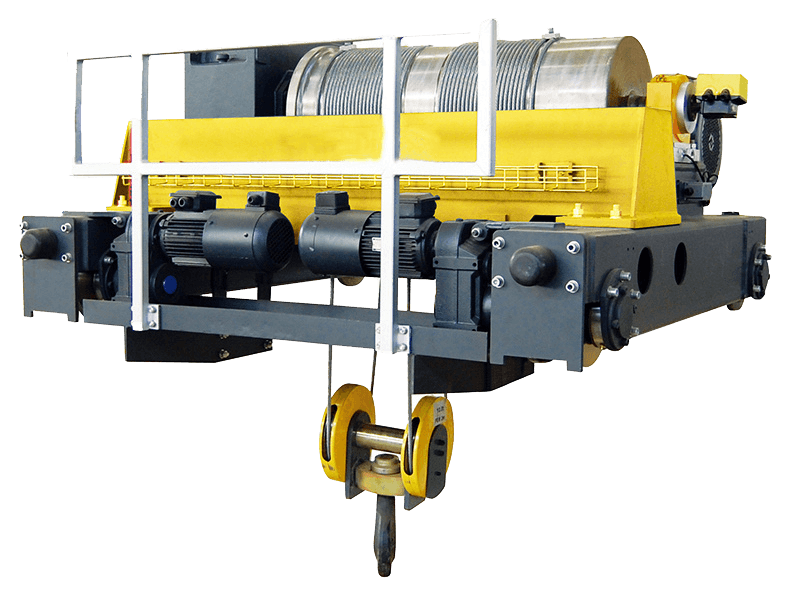

A QD Trolley Crane is a type of double-girder overhead crane that looks like an electric hoist, known for its versatility and strength in lifting heavy loads. “QD” signifies a high-performing double girder system that allows the crane to handle large capacities and operate in demanding environments. The trolley, which travels along the bridge girder, serves as the lifting mechanism and is equipped with a hoist for lifting and moving materials horizontally.

Key Features of QD Trolley Cranes

- High Load Capacity: QD Trolley Cranes can handle loads from 5 tons to over 100 tons, making them suitable for heavy-duty applications.

- Double Girder Design: The dual-girder design enhances stability and allows for a higher lifting capacity compared to single-girder models.

- Flexible Trolley Movement: The trolley can move along the bridge girder, providing horizontal motion, and enabling precise load positioning.

- Robust Construction: Made from high-quality steel, these cranes are built for durability, enabling them to withstand intense industrial environments.

- Enhanced Safety Features: QD Trolley Cranes are equipped with advanced safety features, such as overload protection, emergency stop functions, and anti-collision devices.

Applications of QD Trolley Cranes

Due to their robust design and lifting capacity, QD Trolley Cranes are commonly used in:

- Heavy Manufacturing Industries: Including automotive, aerospace, and steel industries, where lifting and precise positioning of large materials and equipment are crucial.

- Logistics and Warehousing: Used to transport heavy packages and containers across large warehouse spaces.

- Mining and Construction Sites: Where they can handle bulky raw materials and heavy equipment, providing efficient material handling solutions.

- Shipyards and Ports: Ideal for moving heavy shipping containers and large cargo loads.

Advantages of Using QD Trolley Cranes

- Improved Efficiency: The high load capacity and ease of operation reduce time spent on manual handling, allowing for faster load management.

- Enhanced Safety: Built-in safety features and remote control options protect operators from hazards, making QD Trolley Cranes a safer choice for high-risk environments.

- Cost-Effective in the Long Run: Their durability and minimal maintenance requirements make these cranes an economical choice for heavy-duty applications.

- Space Optimization: Unlike floor-mounted cranes, overhead cranes free up floor space, creating more room for operations below.

Key Considerations When Choosing a QD Trolley Crane

When selecting a QD Trolley Crane, keep the following factors in mind to ensure the best match for your needs:

- Load Capacity Requirements: Choose a crane with the load capacity that meets your needs without compromising on safety or efficiency.

- Operating Environment: Consider factors like temperature, dust, and humidity, as these cranes may require special features to operate optimally in harsh environments.

- Span and Height: The span (distance between supports) and the lift height should match the operational requirements of your facility.

- Safety Regulations: Ensure that your crane is compliant with industry standards and safety regulations, especially if you’re operating in an environment with strict safety requirements.

Installation and Maintenance of QD Trolley Cranes

Proper installation and regular maintenance are essential for maximizing the lifespan and performance of QD Trolley Cranes. Installation typically involves securing the crane to its supporting structure and testing all movements to ensure optimal functionality.

Maintenance for QD Trolley Cranes includes:

- Regular Inspections: Periodic checks of the trolley, hoist, and girder structure are necessary to detect wear and tear.

- Lubrication: Applying appropriate lubricants to moving parts reduces friction and prolongs equipment life.

- Safety Checks: Testing emergency brakes, load limiters, and other safety features to ensure they operate effectively.

FAQs About QD Trolley Cranes

Q1: What industries benefit the most from using QD Trolley Cranes?

A: QD Trolley Cranes are ideal for industries with heavy lifting needs, such as manufacturing, logistics, mining, and shipyards. Their high load capacity and flexibility make them versatile for various industrial applications.

Q2: How do I determine the right load capacity for my QD Trolley Crane?

A: Load capacity depends on the heaviest items you need to lift. It’s recommended to choose a crane with a capacity slightly above your maximum load requirement to ensure safe operations.

Q3: What is the lifespan of a QD Trolley Crane?

A: With proper maintenance, QD Trolley Cranes can last anywhere from 10 to 20 years or more. Regular inspections and timely repairs help prolong the crane’s life.

Q4: Can QD Trolley Cranes operate in outdoor environments?

A: Yes, QD Trolley Cranes can be designed for outdoor use. However, special features like weatherproofing and anti-corrosion coatings are recommended to protect against environmental elements.

KCICRANES Crane Winch/Crane Trolley

QD Trolley Cranes are powerful, efficient, and safe solutions for handling heavy loads in industrial settings. By understanding their features, applications, and advantages, you can make informed decisions on selecting and maintaining a QD Trolley Crane that meets your facility’s requirements. Whether you’re looking to improve productivity, enhance safety, or maximize your operational space, investing in a QD Trolley Crane can provide significant long-term benefits.

For more information on QD Trolley Cranes or assistance in choosing the right crane for your business, contact our team at KCICRANES Machinery. We’re here to help you find reliable, durable lifting solutions tailored to your industrial needs.

About KCICRANES Machinery

KCICRANES Machinery is a leading manufacturer of cranes and crane accessories. Our dedication to quality and innovation ensures that our products meet your lifting needs efficiently and safely.

Industrial cranes(overhead cranes, gantry cranes, jib cranes. etc) are complex machines with many parts, each critical for safe and efficient operation. At KCICRANES, we provide an extensive range of replacement parts, including:

1. Wire Rope Hoists

Wire rope hoists are essential components of many industrial cranes. They lift and lower loads with precision, but wear and tear can cause them to degrade over time. KCICRANES offers a variety of hoist replacements crafted with durability and strength to support safe and efficient operations.

2. End Trucks

End trucks carry the weight of the crane and allow it to move along its runway. When end trucks fail, it can halt crane movement entirely. Our end trucks are designed for long-lasting performance and fit seamlessly with different crane types.

3. Winch Trolleys

Also called crane winches, electric winches, and crane trolleys.etc

4. Crane Controls

Control systems are the brain of your crane operations. Faulty controls can lead to erratic movements and safety issues. We offer control system replacements, from handheld remotes to intricate PLC systems, to keep your crane operating smoothly and safely.

5. Power Rotating Blocks and Transfer Cars

Used primarily in transfer applications, power rotating blocks and transfer cars allow cranes to handle and rotate heavy loads. When these components show signs of wear, replacing them can prevent accidents and enhance handling efficiency.

Maintaining Your Industrial Crane: Key Tips

Regular maintenance and timely replacement of parts are vital for any industrial crane. Here are some tips to help extend the life of your equipment:

- Conduct Regular Inspections: Check for wear on hoists, cables, and structural components. Early detection of issues can prevent costly repairs.

- Keep Spare Parts Handy: Having essential spare parts on hand reduces downtime in case of unexpected failures.

- Lubricate Moving Parts: Proper lubrication helps reduce friction and wear on moving parts, especially in high-use environments.

- Stay Compliant with Regulations: Regularly inspect and replace parts as per industry standards to ensure safety and compliance.

FAQs: Replacement and Spare Parts for Industrial Cranes

1. How do I know when a part needs replacing?

Signs like unusual noises, reduced performance, and visible wear are common indicators. Regular inspections can help identify parts that need replacing before they fail.

2. Are KCICRANES parts compatible with all industrial cranes?

Our parts are designed to fit a wide range of crane models. Contact our team to confirm compatibility with your specific crane type.

3. What types of industries do you serve?

KCICRANES serves industries ranging from manufacturing and construction to logistics and shipyards. We tailor our parts to meet the demands of each sector.

4. How quickly can I receive replacement parts from KCICRANES?

We keep many of our parts in stock, ready to ship. Shipping times will depend on your location, but we strive to ensure quick delivery.

If you need any other crane kits, welcome to send a free inquiry.Email:info@kcicranes.com

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com