KCICRANES-Professional Crane Kits Supplier

When it comes to the installation of crane wheels, precision, expertise, and careful planning are crucial. At KCICRANES Machinery, we specialize in manufacturing high-quality crane wheels designed to ensure the smooth and efficient movement of your industrial cranes. In this post, we will guide you through the steps and considerations for the installation of crane wheels, while ensuring that safety and durability are never compromised.

The Importance of Crane Wheel Selection

Crane wheels are engineered to bear the immense weight of cranes, enabling them to traverse beams or tracks effortlessly. Each variant of crane wheel is meticulously crafted to meet the distinct needs of specific operational environments. Hence, understanding the nuances of these wheels is essential for companies to make well-informed decisions when choosing the optimal wheel for their machinery.

1. Preparing for Crane Wheel Installation

Before diving into the installation process, it’s important to first assess the environment in which the crane operates. Factors such as load capacity, wheel type, and operating conditions must be taken into account to select the right crane wheel. KCICRANES Machinery offers a wide variety of crane wheels, including forged steel, cast iron, and specialized alloys, each engineered to handle specific stress levels and environmental factors.

Ensure the crane is properly de-energized and secure before beginning any installation. Having the right tools and safety equipment in place is also essential to prevent accidents and ensure a smooth installation.

2. Step-by-Step Guide to Crane Wheel Installation

- Remove the Old Crane Wheel (if applicable)

If you’re replacing old wheels, the first step is to carefully remove the existing crane wheels. Use proper lifting techniques and equipment to ensure that the wheels are safely detached from the crane’s frame. - Inspect the Crane Frame

Before installing the new wheels, inspect the crane’s wheel assembly for any signs of damage or wear. Ensure the wheel bearings, axles, and mounting components are in good condition. Any issues with these parts could affect the performance of the new crane wheels. - Align the New Crane Wheel

Place the new crane wheel onto the mounting assembly, ensuring that it is properly aligned. Crane wheels, especially those made of heavy-duty materials like cast iron or forged steel, require precise placement to ensure the load is distributed evenly across the wheel and axle. - Install the Wheel Components

Attach the necessary hardware, such as bolts, nuts, and washers, to secure the wheel in place. Tighten all fasteners according to the manufacturer’s specifications to prevent loosening during operation. - Test the Wheel Movement

After the crane wheel installation, manually rotate the crane wheel to check for any unusual resistance or noise. This step ensures that the wheel is properly aligned and that no obstacles are preventing smooth movement.

3. Post-Installation Checks and Maintenance

Once the crane wheel installation is complete, perform a series of post-installation checks to ensure everything is functioning correctly. This includes testing the load-bearing capacity of the crane with the new wheels, checking for any vibrations, and confirming that the crane operates smoothly along the tracks.

Regular maintenance is key to prolonging the lifespan of your crane wheels. KCICRANES Machinery recommends periodic inspections to check for wear and tear, especially if the crane operates in harsh environments. Regular lubrication of the bearings and monitoring of the wheel alignment can prevent costly repairs down the line.

4. Why Choose KCICRANES Machinery for Your Crane Wheel Needs?

At KCICRANES Machinery, we take pride in offering high-quality crane wheels designed to meet the specific needs of your operations. Our wheels are manufactured from durable materials such as forged steel, cast iron, and specialized alloys to ensure optimal performance and long-lasting durability [1]. We understand the importance of safety and reliability, which is why our products undergo rigorous testing and quality control before they are delivered to our customers.

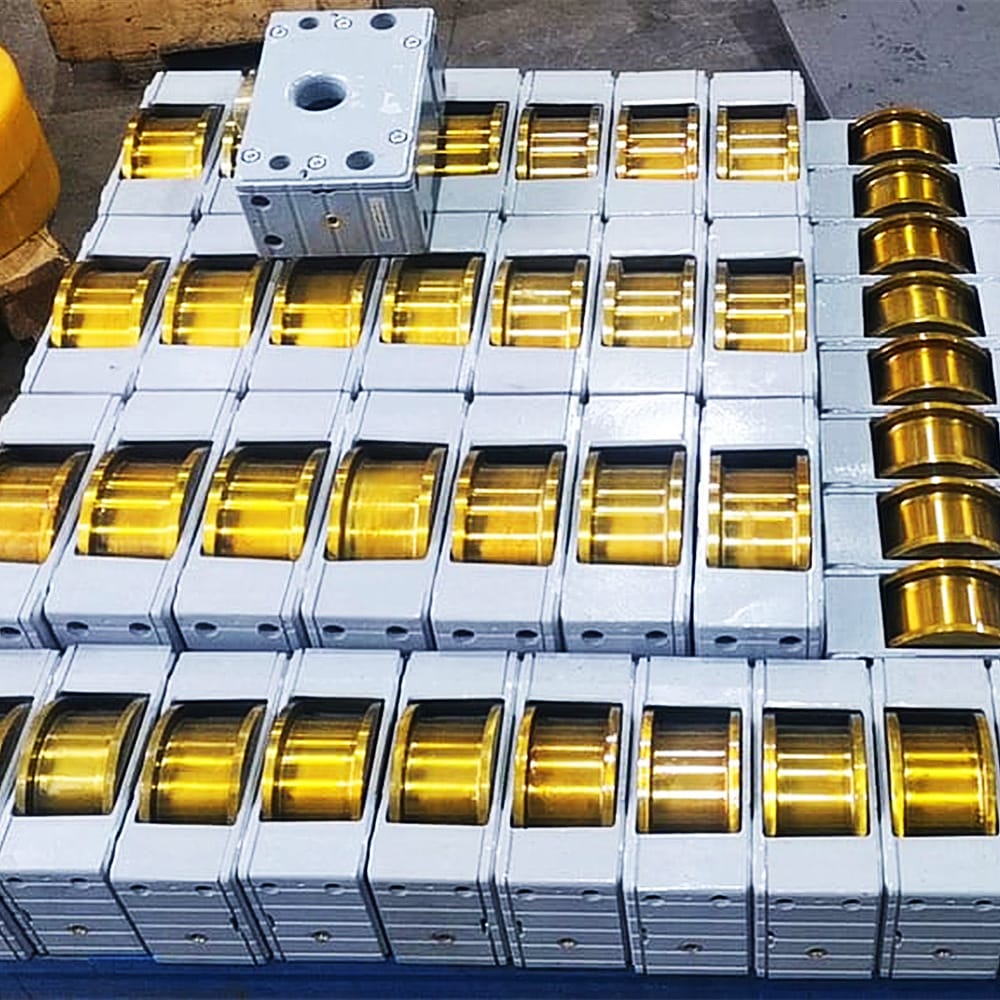

Our expert team is always available to offer guidance and support, whether you are looking to install new crane wheels or require customized solutions for your crane systems. We offer a range of products, including crane wheels, DRS wheel blocks, and other lifting equipment, to meet the unique demands of industries around the world.

5. Contact KCICRANES for Crane Wheel Installation and More

If you are looking for top-quality crane wheels for your operations, KCICRANES Machinery is the name you can trust. Our extensive experience in crane manufacturing ensures that you receive only the best products for your lifting equipment.

For more information on crane wheel installation or to request a custom quote, feel free to contact us at info@kcicranes.com. Our team will be happy to assist you with your specific requirements and provide expert advice to help you get the best results.

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com