KCICRANES-Professional Crane Kits Supplier

Regarding industrial lifting and material handling, the choice of crane wheels plays a crucial role in ensuring durability and efficiency. KCICRANES Machinery is a trusted crane wheel manufacturer that provides high-quality, customizable crane wheels that cater to diverse industries and applications. In this article, we delve into the materials, production processes, diameter range, and application scenarios of crane wheels while showcasing why KCICRANES Machinery is your ideal partner.

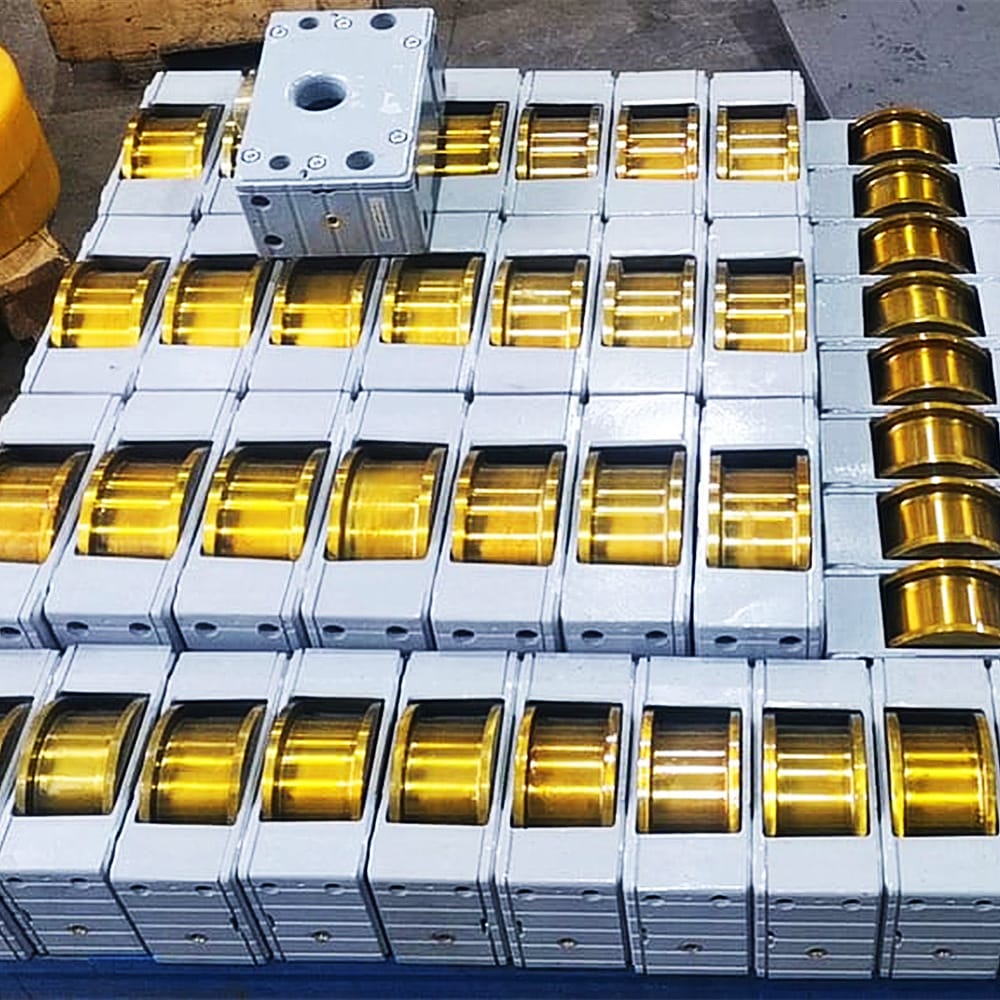

At KCICRANES Machinery, we specialize in designing and producing top-notch crane wheels, along with a wide range of industrial crane components.

We specialize in high-quality crane solutions at KCICRANES Machinery, a leading crane and crane parts manufacturer in China. For inquiries, contact us at info@kcicranes.com.

Good Materials for Long Lasting Performance

The performance of crane wheels depends significantly on the material used in their construction. At KCICRANES Machinery, we utilize high-grade alloy steel and forged steel to manufacture crane wheels. These materials are chosen for their exceptional strength, wear resistance, and ability to withstand heavy loads and harsh operating environments.

Our crane wheels undergo rigorous heat treatment processes, such as quenching and tempering, to enhance their surface hardness and durability. This ensures that the wheels can operate smoothly even under demanding conditions, reducing maintenance costs and downtime.

Advanced Manufacturing Processes

At KCICRANES Machinery, we combine traditional craftsmanship with modern technology to deliver crane wheels of unmatched quality. Our production process involves the following steps:

- Material Selection: We carefully select the appropriate steel grade based on the wheel’s intended application and load capacity requirements.

- Forging and Casting: The wheels are forged or cast to the desired shape, ensuring structural integrity and precision.

- Heat Treatment: Advanced heat treatment processes are applied to enhance the mechanical properties of the wheels, such as hardness and tensile strength.

- Machining: Precision machining ensures that the wheels meet exact specifications and are free from defects.

- Quality Inspection: Each crane wheel undergoes strict quality control checks, including dimensional accuracy, hardness testing, and surface finish evaluation.

Customizable Diameter Range

KCICRANES Machinery offers crane wheels in a wide range of diameters to accommodate various types of cranes and industrial equipment. Whether you need small wheels for light-duty applications or large-diameter wheels for heavy-duty cranes, we have you covered. Our customization services allow you to specify dimensions, load capacities, and other technical requirements to suit your specific operational needs.

Applications Across Diverse Industries

Crane wheels are indispensable in various industrial sectors. Below are some of the key applications of our crane wheels:

- Overhead Cranes: Ensuring smooth and precise movement for bridge and gantry cranes in warehouses and manufacturing plants.

- Port Cranes: Withstanding the heavy loads and corrosive environments typical in port and maritime applications.

- Mining and Construction Equipment: Providing reliable mobility for large-scale equipment operating in challenging conditions.

- Material Handling Systems: Supporting conveyor systems and automated storage and retrieval systems in logistics and warehousing.

Why Choose KCICRANES Machinery as Your Crane Wheel Manufacturer

KCICRANES Machinery is more than just a supplier—we are a partner committed to providing tailored solutions that meet your unique requirements. Here’s why industries worldwide trust us:

- Customization Expertise: We specialize in producing custom crane wheels and DRS wheel blocks, catering to both standard and non-standard requirements.

- Comprehensive Product Range: In addition to crane wheels, we manufacture other crane components such as overhead cranes, gantry cranes, jib cranes, crane trolleys, and transfer carts.

- Stringent Quality Control: Our production processes adhere to strict quality management standards, ensuring that every product leaving our factory is reliable and durable.

- Competitive Pricing: We offer high-quality products at competitive prices, making us a cost-effective choice for your material handling needs.

Partner With Us for Your Crane Wheel Needs

As a leading crane wheel manufacturer, KCICRANES Machinery is dedicated to delivering products that combine performance, reliability, and value. Whether you need standard crane wheels or fully customized solutions, we have the expertise and resources to meet your demands.

Contact us today to learn more about our crane wheels and other industrial lifting products. Let us help you elevate your operations with durable and efficient solutions tailored to your business.

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

When it comes to crane wheels, quality is key. The right wheels can make the difference between smooth, efficient operations and costly, disruptive downtime. By choosing KCICRANES Machinery for your cranes and crane components, you ensure that your crane system operates at peak performance, with safety and durability guaranteed.

For a free inquiry or more information on our products, don’t hesitate to contact us at info@kcicranes.com. Let KCICRANES be your trusted partner in enhancing your crane operations today!

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com