KCICRANES-Professional Crane Kits Supplier

In the realm of industrial machinery, crane wheels are vital components that significantly influence the efficiency and safety of lifting operations. As industries continue to advance, the demand for high-quality crane wheels has surged, leading to the evolution of specialized manufacturing processes. This article provides an in-depth look at crane wheel manufacturing, its importance, and the factors that contribute to producing top-tier crane wheels.

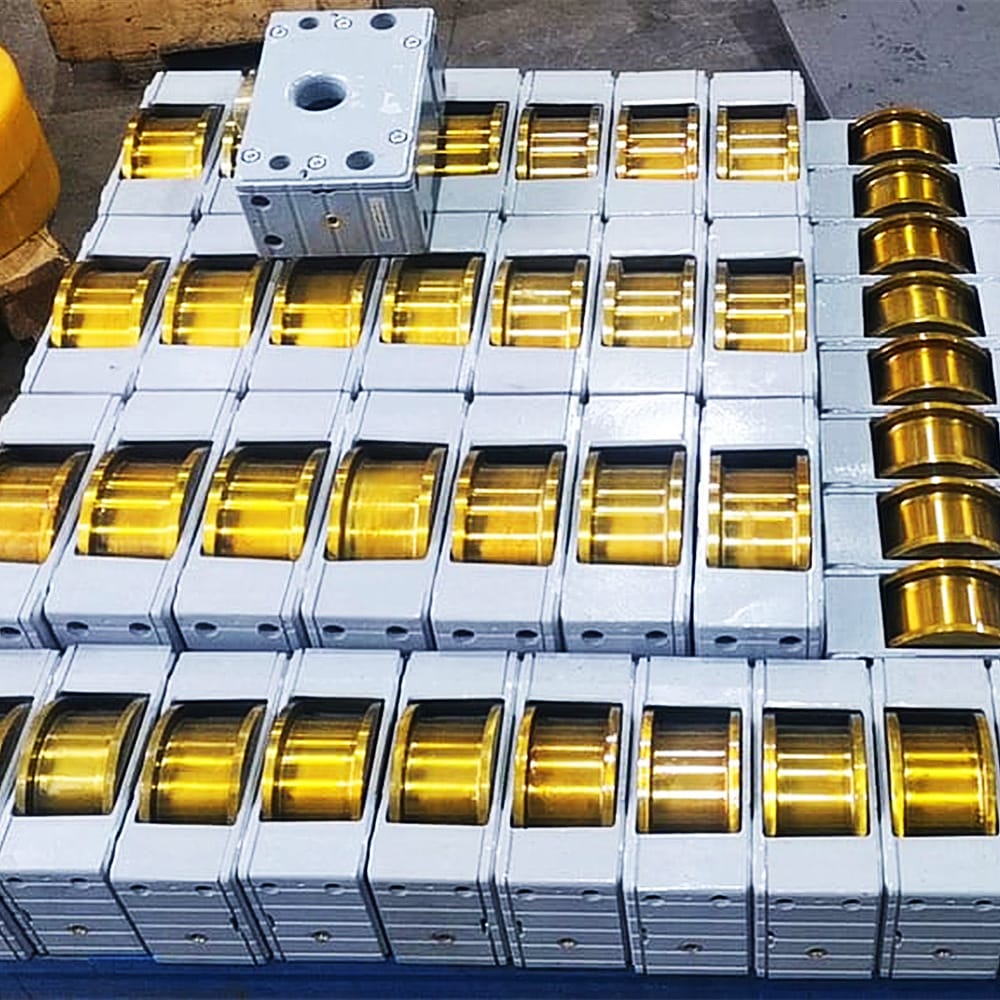

Understanding Crane Wheels

Crane wheels are designed to support the weight of cranes and facilitate smooth movement along tracks or beams. They are critical in various applications, including overhead cranes, gantry cranes, and other lifting equipment. The quality and design of crane wheels directly impact the operational efficiency and safety of lifting systems.

Key Features of Crane Wheels

- Load Capacity: Crane wheels must be engineered to handle specific load capacities, ensuring safe and efficient lifting operations.

- Material Composition: The choice of materials, such as high-strength steel or polyurethane, affects durability, noise levels, and wear resistance.

- Design Variability: Crane wheels can be customized in terms of size, shape, and tread patterns to suit different operational requirements.

- Environmental Resistance: Depending on the application, crane wheels may need to withstand extreme temperatures, moisture, or corrosive substances.

The Manufacturing Process of Crane Wheels

The manufacturing of crane wheels involves several critical steps that ensure the final product meets industry standards and customer specifications.

1. Material Selection

The first step in crane wheel manufacturing is selecting the appropriate materials. High-quality steel is commonly used for heavy-duty applications, while lighter materials like aluminum or composite materials may be chosen for specific uses. The material must possess high tensile strength, durability, and resistance to wear.

2. Design and Engineering

Once the materials are selected, the design phase begins. Engineers create detailed specifications, including dimensions, load capacities, and tread patterns. Advanced CAD (Computer-Aided Design) software is often used to visualize the final product and make necessary adjustments before production.

3. Machining

The machining process involves cutting, shaping, and finishing the raw materials to create the components of crane wheels. Precision machining ensures that each part meets the required tolerances, which is crucial for the overall performance of the crane wheels.

4. Heat Treatment

To enhance the mechanical properties of the crane wheels, heat treatment processes such as quenching and tempering are applied. This step increases hardness and strength, making the wheels more resilient to wear and stress.

5. Assembly

After machining and heat treatment, the various components of the crane wheels are assembled. This may include fitting bearings, seals, and any additional components needed for optimal performance.

6. Quality Control

Quality control is a critical phase in crane wheel manufacturing. Each batch of crane wheels undergoes rigorous testing to ensure they meet safety and performance standards. This may involve load testing, dimensional checks, and inspections for surface defects.

7. Finishing Touches

The final step in the manufacturing process includes surface treatments such as painting or coating to enhance corrosion resistance and aesthetic appeal. Proper finishing also contributes to the longevity of the crane wheels.

Benefits of High-Quality Crane Wheel Manufacturing

Investing in high-quality crane wheels manufactured with precision offers several benefits:

1. Enhanced Safety

Quality crane wheels reduce the risk of accidents during lifting operations. Properly manufactured wheels ensure stability and control, minimizing the chances of equipment failure.

2. Increased Efficiency

Well-designed crane wheels facilitate smoother movement, which can significantly enhance operational efficiency. Reduced friction and wear lead to lower energy consumption and faster cycle times.

3. Longevity

High-quality materials and manufacturing processes result in durable crane wheels that can withstand harsh operating conditions. This longevity reduces replacement frequency and maintenance costs.

4. Customization Options

Many manufacturers, including KCICRANES Machinery, offer customization options for crane wheels. This allows businesses to tailor products to their specific needs, enhancing overall functionality.

KCICRANES Machinery: Your Trusted Manufacturer

KCICRANES Machinery is a professional crane manufacturer based in China, specializing in a wide range of products, including:

- Overhead Cranes

- Gantry Cranes

- Crane Wheels

- Crane Beams

- Grab Buckets

- Open Winches

- Electric Hoists

Our commitment to quality and customer satisfaction sets us apart in the industry. We utilize advanced manufacturing techniques and rigorous quality control measures to ensure that our crane wheels meet the highest standards.

Why Choose KCICRANES for Your Crane Wheel Needs?

- Expertise: With extensive experience in crane manufacturing, our team understands the nuances of producing high-quality crane wheels.

- Customization: We offer tailored solutions to meet specific operational requirements, ensuring you receive the perfect crane wheels for your application.

- Quality Assurance: Our products undergo thorough testing to guarantee performance and safety, giving you peace of mind.

- Competitive Pricing: We provide high-quality crane wheels at competitive prices, ensuring excellent value for your investment.

- Comprehensive Support: From the initial inquiry to post-purchase assistance, our team is dedicated to supporting you throughout the process.

FAQs About Crane Wheel Manufacturing

1. What materials are commonly used in crane wheel manufacturing?

Common materials include high-strength steel for durability and polyurethane for quieter operations and reduced wear.

2. How do I determine the right specifications for crane wheels?

Consulting with a manufacturer can help you assess your operational needs, including load capacity, dimensions, and environmental conditions.

3. Can crane wheels be customized for specific applications?

Yes, many manufacturers offer customization options to tailor crane wheels to meet specific operational requirements.

4. What is the typical lifespan of crane wheels?

The lifespan of crane wheels varies based on material, usage, and maintenance practices. High-quality wheels can last several years with proper care.

5. How can I ensure the quality of crane wheels?

Choose a reputable manufacturer that follows strict quality control processes and offers warranties on their products.

Embracing the Future of Crane Wheel Manufacturing

The landscape of crane wheel manufacturing continues to evolve, driven by advancements in technology and the increasing demand for specialized equipment. By prioritizing quality, safety, and customization, manufacturers like KCICRANES Machinery are setting new standards in the industry. As businesses seek to enhance their operational efficiency, investing in high-quality crane wheels becomes paramount. Whether you need standard or custom solutions, KCICRANES is here to provide the best options tailored to your needs. For inquiries, feel free to reach out at info@kcicranes.com

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com