KCICRANES-DRS Crane Wheel System Manufacturer in China

Crane wheels are essential components of industrial cranes, responsible for smooth movement along rails while carrying heavy loads. Over time, crane wheels may wear out due to constant stress and need to be replaced to ensure the safety and efficiency of your equipment. This article provides an in-depth guide on crane wheel replacement, covering key considerations, material types, and maintenance tips. At KCICRANES Machinery, we specialize in high-quality, customizable crane wheels at competitive prices. Contact us at Email: info@kcicranes.com for your crane wheel needs.

DRS Wheel Block System Manufacturer in China: A Comprehensive Overview

In the rapidly evolving world of industrial machinery, the DRS Wheel Block System plays a pivotal role in ensuring operational efficiency and safety in crane systems. As a leading manufacturer based in China, KCICRANES Machinery specializes in producing high-quality wheel block systems that cater to various industrial needs. This article delves into the intricacies of the DRS Wheel Block System, its significance, and the advantages of choosing KCICRANES as your trusted supplier.

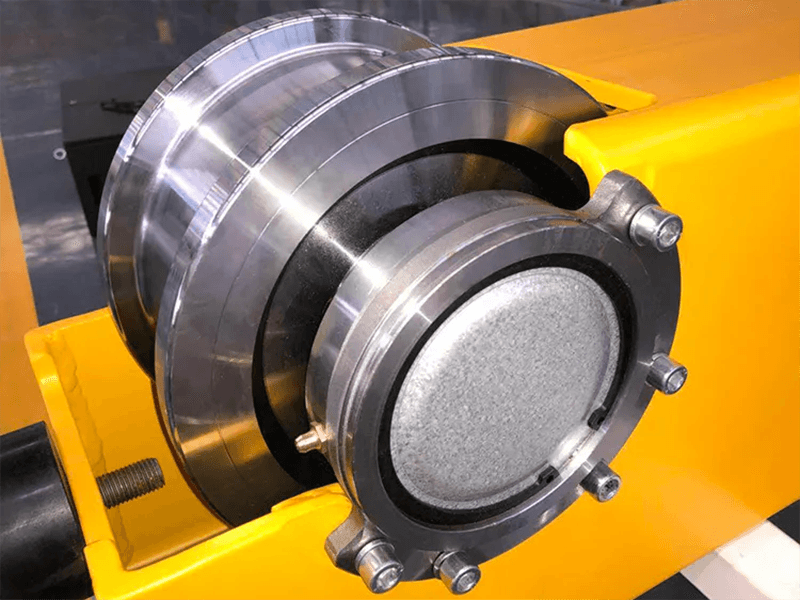

Understanding the DRS Wheel Block System

The DRS Wheel Block System is an essential component in crane operations, designed to facilitate smooth movement and stability of cranes. It consists of a robust assembly that includes wheels, bearings, and a block housing, allowing for seamless transportation of heavy loads.

Key Features of the DRS Crane Wheel System

- Durability: Constructed from high-grade materials, the DRS Wheel Block System is engineered to withstand heavy loads and harsh environmental conditions, ensuring longevity and reliability.

- Precision Engineering: The system is designed with precision to minimize friction and wear, enhancing the overall performance of cranes.

- Versatility: Suitable for various applications, the DRS Wheel Block System can be integrated into different types of cranes, including overhead and gantry cranes.

- Safety Standards: Adhering to international safety standards, the DRS Wheel Block System is equipped with features that enhance safety during operation, reducing the risk of accidents.

Why Choose KCICRANES Machinery?

As a professional crane manufacturer in China, KCICRANES Machinery stands out in the industry for several reasons:

1. Extensive Experience

With years of experience in manufacturing crane components, KCICRANES has honed its expertise in producing high-quality DRS Wheel Block Systems. Our commitment to excellence ensures that each product meets the highest standards of quality and performance.

2. Comprehensive Product Range

In addition to the DRS Wheel Block System, KCICRANES offers a wide array of products, including:

- Overhead Cranes: Designed for efficient lifting and moving of materials in various industrial settings.

- Gantry Cranes: Ideal for outdoor applications, providing flexibility in lifting operations.

- Crane Wheels: Engineered for durability and performance, ensuring smooth movement.

- Crane Beams: Customizable to meet specific load requirements.

- Grab Buckets: Perfect for handling bulk materials.

- Open Winches and Electric Hoists: Essential for lifting heavy loads with ease.

3. Customer-Centric Approach

At KCICRANES, we prioritize our customers’ needs. Our team of experts works closely with clients to understand their requirements and provide tailored solutions. We welcome inquiries and are committed to offering competitive pricing without compromising on quality.

4. Advanced Manufacturing Techniques

Utilizing state-of-the-art manufacturing techniques and technologies, KCICRANES ensures that every DRS Wheel Block System is produced with precision. Our facilities are equipped with the latest machinery to enhance efficiency and product quality.

The Importance of the DRS Wheel Block System in Crane Operations

The DRS Wheel Block System is crucial for several reasons:

- Enhanced Mobility: The system allows cranes to move smoothly along tracks, facilitating efficient material handling in warehouses and construction sites.

- Load Distribution: Properly designed wheel blocks ensure even distribution of loads, preventing structural damage to cranes and enhancing safety.

- Reduced Maintenance Costs: The durability and efficiency of the DRS Wheel Block System lead to lower maintenance requirements, saving costs in the long run.

- Increased Productivity: With smoother operations, cranes equipped with high-quality wheel block systems can complete tasks more quickly, improving overall productivity.

FAQs About DRS Wheel Block System Manufacturer in China

1. What materials are used in the DRS Wheel Block System?

The DRS Wheel Block System is typically made from high-strength steel and other durable materials that can withstand heavy loads and harsh conditions.

2. How do I choose the right DRS Wheel Block System for my crane?

Choosing the right system depends on several factors, including the load capacity, the type of crane, and the specific application. Consulting with a manufacturer like KCICRANES can help you make an informed decision.

3. What is the typical lifespan of a DRS Wheel Block System?

With proper maintenance, a DRS Wheel Block System can last several years. Regular inspections and timely replacements of worn components can significantly extend its lifespan.

4. Are there customization options available for the DRS Wheel Block System?

Yes, KCICRANES offers customization options to meet specific requirements, including size, load capacity, and material specifications.

5. How can I ensure the safety of my crane operations with the DRS Wheel Block System?

Regular maintenance, adherence to safety protocols, and using high-quality components like the DRS Wheel Block System from KCICRANES can significantly enhance the safety of crane operations.

In conclusion, the DRS Wheel Block System is an indispensable component for efficient and safe crane operations. As a leading manufacturer in China, KCICRANES Machinery is committed to delivering high-quality products that meet the diverse needs of our clients. Our extensive range of products, coupled with our dedication to customer satisfaction, makes us the ideal partner for your crane solutions.

For any inquiries or to learn more about our products, feel free to contact us at info@kcicranes.com. We look forward to helping you enhance your operations with our advanced crane technology.

Contact Us

If you are looking for reliable and durable crane wheels, KCICRANES Machinery is your trusted partner. Whether you need standard wheels or custom designs, we are here to help. Contact us at:

Email: info@kcicranes.com

About KCICRANES Machinery

KCICRANES Machinery is a leading manufacturer of cranes and crane accessories. Our dedication to quality and innovation ensures that our products meet your lifting needs efficiently and safely.

Industrial cranes(overhead cranes, gantry cranes, jib cranes. etc) are complex machines with many parts, each critical for safe and efficient operation. At KCICRANES, we provide an extensive range of replacement parts, including:

1. Wire Rope Hoists

Wire rope hoists are essential components of many industrial cranes. They lift and lower loads precisely, but wear and tear can cause them to degrade over time. KCICRANES offers a variety of hoist replacements crafted with durability and strength to support safe and efficient operations.

2. End Trucks

End trucks carry the crane’s weight and allow it to move along its runway. When end trucks fail, crane movement can be entirely halted. Our end trucks are designed for long-lasting performance and fit seamlessly with different crane types.

3. Winch Trolleys

Also called crane winches, electric winches, and crane trolleys.etc

4. Crane Controls

Control systems are the brains of your crane operations. Faulty controls can lead to erratic movements and safety issues. We offer control system replacements, from handheld remotes to intricate PLC systems, to keep your crane operating smoothly and safely.

5. Power Rotating Blocks and Transfer Carts

Used primarily in transfer applications, power rotating blocks and transfer cars allow cranes to handle and rotate heavy loads. When these components show signs of wear, replacing them can prevent accidents and enhance handling efficiency.

Maintaining Your Industrial Crane: Key Tips

Regular maintenance and timely replacement of parts are vital for any industrial crane. Here are some tips to help extend the life of your equipment:

- Conduct Regular Inspections: Check for wear on hoists, cables, and structural components. Early detection of issues can prevent costly repairs.

- Keep Spare Parts Handy: Having essential spare parts on hand reduces downtime in case of unexpected failures.

- Lubricate Moving Parts: Proper lubrication helps reduce friction and wear on moving parts, especially in high-use environments.

- Stay Compliant with Regulations: Regularly inspect and replace parts as per industry standards to ensure safety and compliance.

FAQs: Replacement and Spare Parts for Industrial Cranes

1. How do I know when a part needs replacing?

Signs like unusual noises, reduced performance, and visible wear are common indicators. Regular inspections can help identify parts that need replacing before they fail.

2. Are KCICRANES parts compatible with all industrial cranes?

Our parts are designed to fit a wide range of crane models. Contact our team to confirm compatibility with your specific crane type.

3. What types of industries do you serve?

KCICRANES serves industries ranging from manufacturing and construction to logistics and shipyards. We tailor our parts to meet the demands of each sector.

4. How quickly can I receive replacement parts from KCICRANES?

We keep many of our parts in stock, ready to ship. Shipping times will depend on your location, but we strive to ensure quick delivery.

If you need any other crane kits, welcome to send a free inquiry.Email:info@kcicranes.com

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com