KCICRANES-Professional Crane Kits Supplier

In the world of heavy industrial lifting and transportation, the efficient and safe operation of cranes is paramount. Overhead crane systems, commonly referred to as EOT (Electric Overhead Traveling) cranes rely on several critical components for smooth functioning, and one such component is the EOT crane wheel. These wheels play an essential role in supporting the crane structure, ensuring load stability, and enabling safe movement of heavy materials across industrial facilities.

In this article, we will explore the key aspects of EOT crane wheels, their importance, types, material selection, maintenance, and how they contribute to the overall performance of crane systems.

We specialize in high-quality crane solutions at KCICRANES Machinery, a leading crane and crane parts manufacturer in China. For inquiries, contact us at info@kcicranes.com.

What is an EOT Crane Wheel?

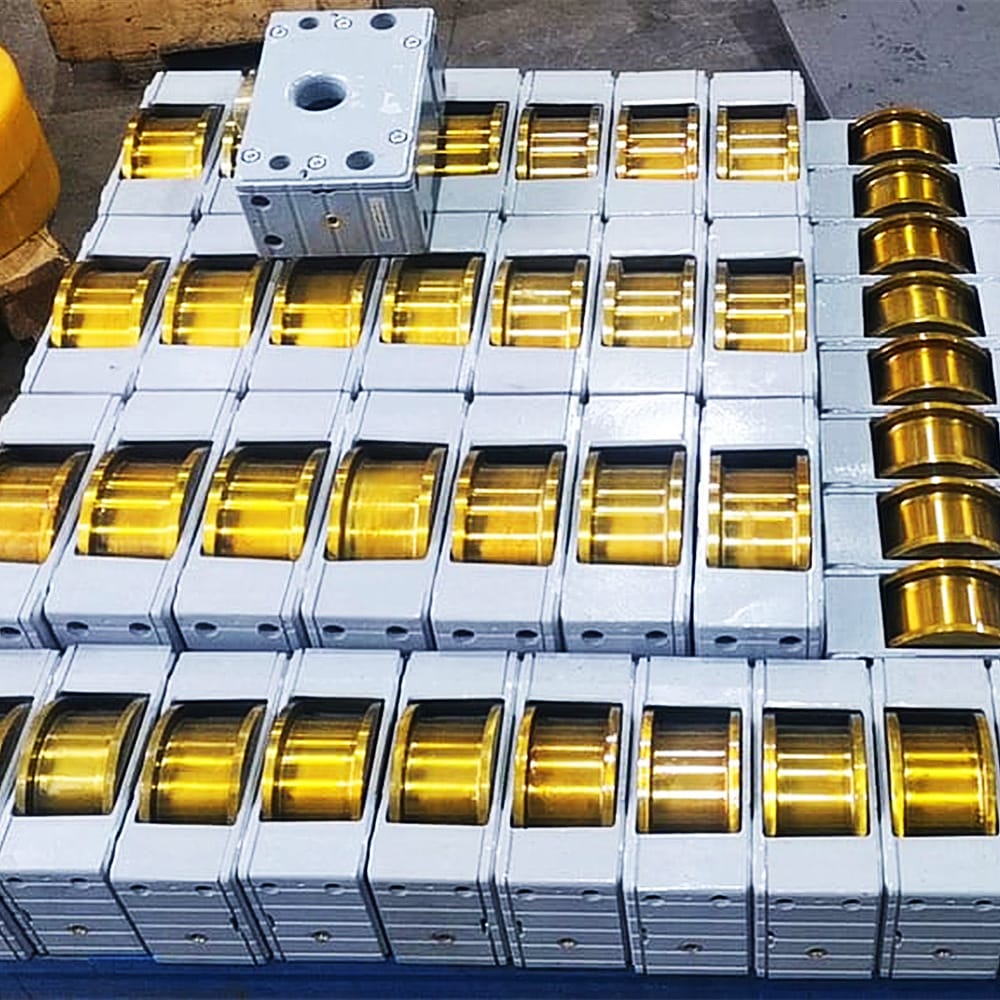

An EOT crane wheel is a specifically designed wheel used in overhead cranes to support the load of the crane and facilitate smooth movement along the rail track. These wheels are a critical part of the crane’s rail-guided movement, enabling the crane to traverse horizontally across the facility with ease. They are often made from durable, high-strength materials to withstand extreme stress, high temperatures, and continuous motion under heavy load conditions.

Key Functions of EOT Crane Wheels

The role of the EOT crane wheel extends beyond simply supporting the crane’s structure. Some of the key functions they serve include:

- Load Distribution: The crane wheels bear the weight of both the crane and any materials it lifts. This requires the wheels to be designed to distribute the load evenly across their surfaces.

- Smooth Movement: Crane wheels enable smooth and efficient movement along the rail system. Their design ensures the crane travels without jerks or instability, thus reducing operational wear and tear.

- Minimizing Wear and Tear: The wheels are engineered to endure constant motion and weight-bearing, leading to significant wear if not properly designed or maintained.

Types of EOT Crane Wheels

EOT crane wheels come in various types, each suited for different applications depending on the nature of the crane system and the load it is required to carry. The most common types include:

- Solid Crane Wheels: Solid wheels are made from a single piece of metal and offer exceptional strength and durability. They are ideal for handling high-impact, heavy-duty loads, and are commonly used in industrial crane systems.

- Forged Crane Wheels: These wheels are forged from high-quality steel to enhance their strength and resilience. Forged wheels are resistant to cracking under pressure and are suitable for cranes operating in challenging conditions.

- Cast Crane Wheels: Cast wheels are typically used for medium-duty applications. These wheels are formed by pouring molten metal into molds, resulting in a cost-effective yet durable solution for many crane operations.

- Tapered Crane Wheels: Tapered wheels feature a conical shape and are designed to ensure proper alignment with the crane rails. Their shape helps to reduce friction during crane movement and enhance operational efficiency.

Material Selection for EOT Crane Wheels

The material used in manufacturing EOT crane wheels is crucial to their performance and longevity. Crane wheels must endure extreme operating conditions, including heavy loads, shock impact, and constant motion. Common materials used in the production of crane wheels include:

- Carbon Steel: Carbon steel is one of the most commonly used materials for crane wheels due to its excellent strength and durability. It is often alloyed with other elements to enhance its resistance to wear and corrosion.

- Alloy Steel: For more demanding applications, alloy steel may be used. It offers improved toughness and resistance to high temperatures and wear, making it suitable for heavy-duty EOT crane wheel systems.

- Cast Iron: Cast iron is an affordable material that can withstand considerable pressure. It is commonly used for light to medium-duty crane systems but may not be suitable for extreme conditions.

- Heat-Treated Steel: Heat treatment processes are used to enhance the hardness and strength of steel, making it ideal for use in crane wheels that are subjected to high-impact forces.

Importance of EOT Crane Wheel Design

The design of EOT crane wheels is essential for the optimal performance and safety of crane systems. The wheels are typically designed to have a wide flange to ensure stable guidance on the track and prevent derailment. The profile of the wheel also plays a significant role in ensuring smooth movement with minimal friction.

- Wheel Diameter: The diameter of the wheel must be large enough to support heavy loads without excessive wear. A larger diameter also reduces the frequency of replacements and maintenance.

- Wheel Width: The width of the wheel affects its ability to distribute the weight evenly. A wider wheel provides better support, especially for larger cranes carrying heavy materials.

- Tread Profile: The tread profile (the contact surface between the wheel and the rail) must be carefully designed to prevent excessive friction and heat buildup. A proper tread profile ensures optimal movement while minimizing wear on both the wheel and the rail.

Factors Affecting EOT Crane Wheel Performance

Several factors influence the performance and longevity of EOT crane wheels. Understanding these factors can help in maintaining and extending the lifespan of crane systems.

- Load Capacity: The load capacity of the crane system will directly impact the performance of the wheels. Overloading can lead to premature wear and potential wheel failure.

- Track Alignment: Misaligned tracks can cause uneven wear on crane wheels, leading to reduced efficiency and safety risks. Regular inspections and alignment checks are essential.

- Operational Speed: Higher speeds generate greater friction, which can result in faster wear of the crane wheels. Monitoring operational speeds is crucial to ensure optimal performance and longevity.

- Environmental Conditions: Crane wheels exposed to harsh environmental conditions, such as high humidity, extreme temperatures, or corrosive substances, will experience accelerated wear. Protective coatings or corrosion-resistant materials can help mitigate these risks.

Maintenance of EOT Crane Wheels

Routine maintenance and timely repairs are vital to ensuring the longevity of EOT crane wheels and the overall crane system. Some important maintenance practices include:

- Regular Inspections: Inspecting the wheels for cracks, wear, or any other signs of damage can help identify issues before they lead to failure. Pay particular attention to the wheel flange and tread surface.

- Lubrication: Proper lubrication of the wheel bearings helps reduce friction and wear, ensuring smoother crane movement and extended service life.

- Rail Inspection and Alignment: Inspecting the crane rails for damage or misalignment helps to reduce unnecessary stress on the wheels, improving their lifespan and ensuring safe operation.

- Wheel Reconditioning: Over time, the wheels may wear down and require reconditioning. This can involve resurfacing or reshaping the wheel to restore its performance.

EOT crane wheels are an integral part of the crane system, and their performance directly impacts the efficiency and safety of crane operations. By selecting the right material, ensuring proper design, and adhering to a routine maintenance schedule, companies can extend the lifespan of their crane wheels and reduce the risk of operational downtime. Whether it’s for heavy-duty industrial applications or lighter crane systems, understanding the complexities of EOT crane wheels is essential for ensuring optimal performance and minimizing maintenance costs.

KCICRANES Machinery is a professional industrial crane supplier in China, specializing in the production of overhead cranes, gantry cranes, crane wheels, crane hoists, crane drums, busbars, and transfer trolleys. We offer high-quality products designed for reliability and durability. For free inquiries or more information, please contact us at info@kcicranes.com

Choosing the Right Crane Wheel

When deciding between forged and cast crane wheels, consider the following:

- Load Requirements: For heavy-duty tasks, forged wheels provide unmatched strength and durability.

- Budget: If cost is a constraint and the application isn’t demanding, cast wheels can be a practical choice.

- Environment: For outdoor or high-stress environments, forged wheels are the safer, longer-lasting option.

- Maintenance: Forged wheels require less frequent replacement, reducing downtime and maintenance costs.

Why Choose KCICRANES Machinery?

At KCICRANES Machinery, we understand the importance of reliable crane components. Our forged crane wheels are manufactured to the highest standards, ensuring exceptional performance and longevity. Whether you need a standard design or a custom solution, we’ve got you covered.

Contact us at info@kcicranes.com for more information or to get a quote.

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com