KCICRANES-Professional Crane Kits Supplier

Gantry cranes are widely used in various industrial applications, and their performance heavily depends on the quality of their wheels. Gantry crane wheels play a crucial role in ensuring the crane’s smooth movement and the safe transportation of heavy loads. At KCICRANES Machinery, we specialize in manufacturing durable and reliable gantry crane wheels, designed to meet the rigorous demands of heavy-duty lifting.

The Importance of Crane Wheel Selection

Crane wheels are engineered to bear the immense weight of cranes, enabling them to traverse beams or tracks effortlessly. Each variant of crane wheel is meticulously crafted to meet the distinct needs of specific operational environments. Hence, understanding the nuances of these wheels is essential for companies to make well-informed decisions when choosing the optimal wheel for their machinery.

1. What are Gantry Crane Wheels?

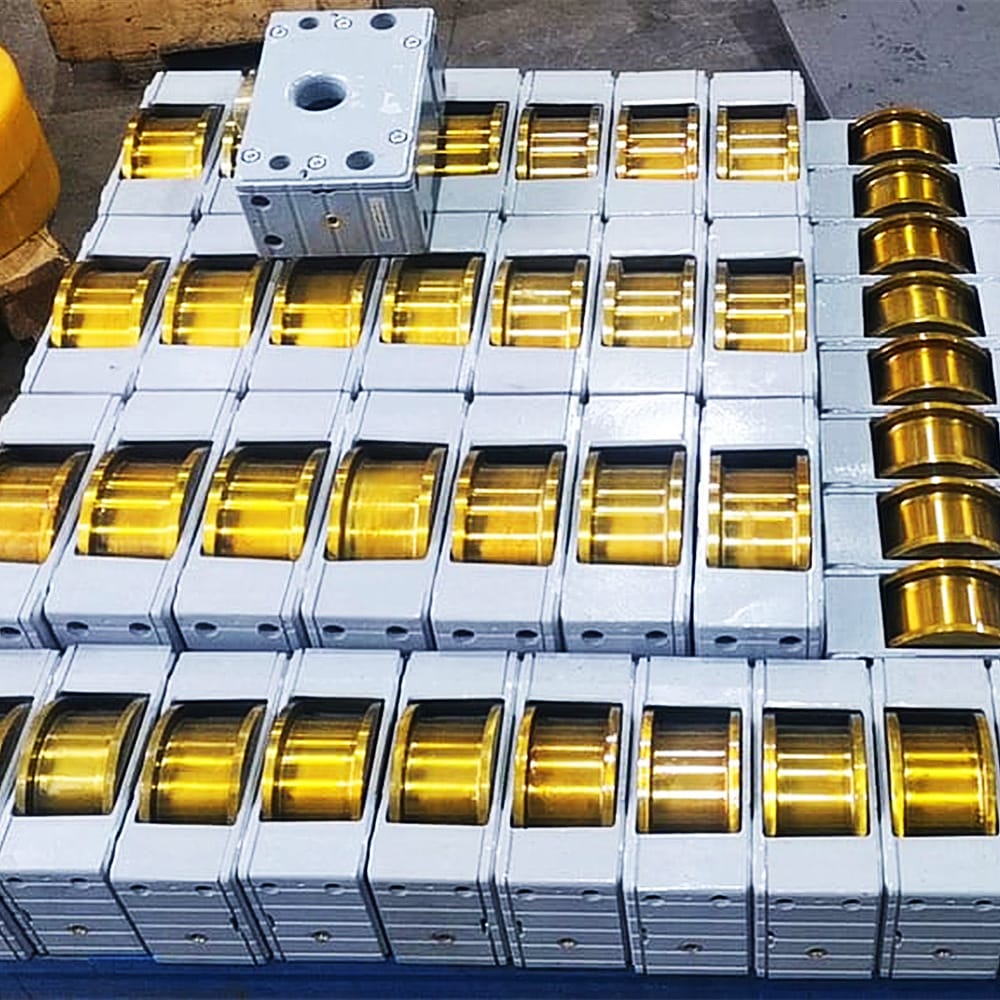

Gantry crane wheels are heavy-duty components that allow gantry cranes to move along tracks or rails. These wheels support the weight of the crane and ensure stable operation under heavy loads. As a crucial part of the gantry crane system, they ensure that the crane operates efficiently, with minimal friction and maximum stability.

2. Materials Used in Gantry Crane Wheels

The material used to produce gantry crane wheels plays a key role in determining their strength, durability, and performance. At KCICRANES Machinery, we use high-quality materials such as forged steel, cast iron, and specialized alloys. These materials are carefully selected to withstand the immense pressure and stress exerted on the wheels during lifting operations.

- Forged Steel: Known for its strength and durability, forged steel is ideal for gantry crane wheels that are used in heavy-duty applications.

- Cast Iron: Cast iron is a strong and wear-resistant material, commonly used in environments where heavy loads are frequently moved.

- Specialized Alloys: For specific operational requirements, we offer wheels made from specialized alloys, ensuring that each customer’s needs are met.

3. Production of Gantry Crane Wheels

The production process of gantry crane wheels involves several stages, starting with the selection of the right materials. Once the materials are chosen, they are shaped and forged using advanced manufacturing techniques. This process ensures that the wheels are strong, wear-resistant, and able to handle the heavy loads typically associated with industrial lifting.

After the wheels are formed, they undergo heat treatment to further enhance their strength and durability. Finally, the wheels are inspected for quality assurance, ensuring that each set meets strict performance standards.

4. Applications of Crane Wheels

Crane wheels are widely used in various industries, including construction, shipping, and manufacturing. These wheels are essential in applications where cranes need to move large and heavy loads across a track or rail system.

- Heavy Lifting: Crane wheel system are used in cranes that lift heavy materials such as steel beams, large containers, and machinery.

- Shipping Ports: In ports, gantry cranes move containers on and off ships, and the wheels must be able to handle the heavy weight and ensure smooth movement.

- Construction Sites: At construction sites, gantry cranes are used to lift and position large materials, requiring high-performance wheels to facilitate quick and efficient movement.

5. Advantages of Crane Wheels made by KCICRANES Machinery

There are several advantages to using high-quality crane wheel system, especially those produced by KCICRANES Machinery:

- Durability: Our gantry crane wheels are built to last. They are designed to withstand the constant stress and wear that comes with heavy lifting.

- Efficiency: High-quality wheels ensure smooth movement, reducing friction and energy consumption, which leads to more efficient crane operation.

- Customization: At KCICRANES, we offer customized solutions to meet the specific needs of our clients. Whether you need wheels for heavy-duty cranes or lighter applications, we can tailor the wheels to fit your requirements.

- Safety: Properly functioning gantry crane wheels help ensure safe operations, preventing accidents and reducing the risk of crane malfunction.

6. Choosing the Right Gantry Crane Wheels

When selecting gantry crane wheels, it’s important to consider factors such as the weight of the loads being lifted, the type of environment in which the crane operates, and the specific design of the crane. Our team at KCICRANES Machinery can help you choose the right crane wheels for your needs.

7. Why Choose KCICRANES for Your Gantry Crane Wheels?

KCICRANES Machinery is a trusted name in the industry, specializing in the production of high-quality crane components, including gantry crane wheels. Our products are designed to meet the highest standards of safety, durability, and performance.

- Expertise: We have years of experience in crane manufacturing and understand the intricacies of producing top-notch gantry crane wheels.

- Customization: We offer customized solutions tailored to your specific operational needs.

- Quality Assurance: All our products go through rigorous testing to ensure they meet performance and safety standards.

- Competitive Pricing: We offer high-quality gantry crane wheels at competitive prices, ensuring that you get the best value for your investment.

8. Contact Us for Gantry Crane Wheels

If you need high-quality gantry crane wheels for your lifting operations, contact KCICRANES Machinery today. We offer both standard and customized solutions, ensuring that you receive the best products for your application. For inquiries, please email us at info@kcicranes.com.

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com