KCICRANES-Professional Crane Kits Supplier

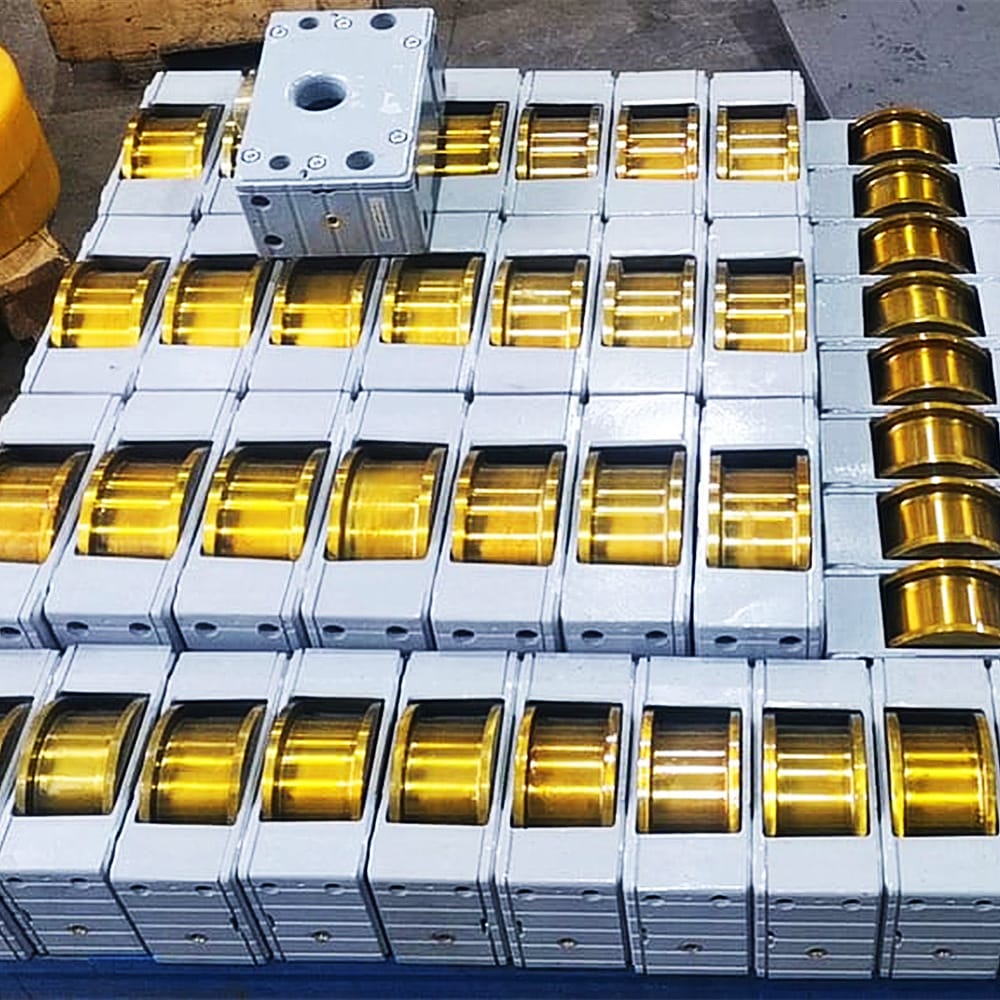

In industrial lifting, the overhead crane is a cornerstone of operational efficiency, playing a vital role across sectors ranging from construction to manufacturing. Central to the optimal performance of these cranes are their wheels—robust components that ensure stability, precision, and seamless movement under intense operational stress. At KCICRANES Machinery, we specialize in designing and producing high-performance overhead crane wheels, engineered to excel in the most demanding environments and ensure that your lifting operations run smoothly, safely, and efficiently.

The Importance of Crane Wheel Selection

Crane wheels are engineered to bear the immense weight of cranes, enabling them to traverse beams or tracks effortlessly. Each variant of the crane wheel is meticulously crafted to meet the distinct needs of specific operational environments. Hence, understanding the nuances of these wheels is essential for companies to make well-informed decisions when choosing the optimal wheel for their machinery.

1. Defining Overhead Crane Wheels

Overhead crane wheels are more than mere components; they are the bedrock upon which the crane’s entire functionality relies. These heavy-duty wheels support the crane’s substantial weight while enabling it to traverse tracks or rails with minimal friction. As the primary interface between the crane and the track, the wheels must withstand considerable force, making their design and durability crucial to the crane’s overall performance and longevity. A crane’s efficiency, particularly under heavy load conditions, is directly influenced by the quality and construction of its wheels.

2. The Materials Behind Overhead Crane Wheels

The materials selected for the manufacture of crane wheels dictate their strength, durability, and performance under extreme conditions. At KCICRANES, we utilize a range of high-grade materials to produce crane wheels that offer exceptional wear resistance, long service life, and optimal functionality.

- Forged Steel: Known for its exceptional toughness, forged steel is the material of choice for high-stress lifting applications. Its dense, solid structure ensures that the wheel can withstand significant loads without deforming, making it ideal for heavy-duty cranes.

- Cast Iron: Often chosen for its excellent wear resistance, cast iron is ideal for environments where heavy loads and constant friction are the norm. It is particularly suited for cranes operating in harsh industrial settings where durability is key.

- Stainless Steel: Offering superior corrosion resistance, stainless steel is invaluable in cranes operating in challenging environments—such as those exposed to high humidity, chemicals, or saltwater, as often found in port facilities and chemical plants.

3. The Manufacturing Process of Overhead Crane Wheels

The production of steel wheel is a meticulous and highly technical process, involving several stages designed to enhance the material’s strength and performance. Here’s a closer look at the process:

- Material Selection: Choosing the right material for the specific application is the first and most critical step. The material must align with the crane’s operational demands—whether it’s strength, wear resistance, or corrosion resistance.

- Forging and Shaping: The selected material undergoes forging, a process that involves heating the material and shaping it into the wheel’s required dimensions. This technique enhances the material’s structural integrity, creating a wheel capable of enduring high stress and intense load-bearing conditions.

- Heat Treatment: Once shaped, the wheel is subjected to heat treatment to further increase its hardness and durability. This ensures the wheels are ready to handle the immense pressure and friction inherent in heavy lifting operations.

- Quality Control: After production, each wheel undergoes a stringent quality control process. This involves thorough testing to assess strength, durability, wear resistance, and overall performance, ensuring the final product adheres to the highest industry standards.

4. Applications of Overhead Crane Wheels

Overhead crane wheels are indispensable across a variety of industries, each with its unique demands and challenges:

- Manufacturing Plants: Overhead cranes are integral to factories, where they are used to move raw materials, semi-finished goods, and completed products. The wheels must support frequent operation, handling the weight of heavy loads and ensuring uninterrupted production flow.

- Shipping Ports: In port facilities, overhead cranes equipped with high-quality wheels are used to load and unload containers from ships. These wheels are essential for ensuring smooth, efficient, and safe handling of cargo under tight schedules.

- Construction Sites: On construction sites, overhead cranes play a critical role in lifting and positioning massive construction materials, such as steel beams, concrete panels, and large machinery. The wheels must be durable enough to manage the substantial weight and rigorous working conditions typical of construction environments.

5. Advantages of KCICRANES Crane Wheels

- Longevity and Durability: Constructed from the finest materials, our crane wheels are designed to resist wear, providing extended service life and reducing the frequency of replacements.

- Smooth Operation: Precision-engineered wheels reduce friction, ensuring smoother travel along crane rails and optimizing operational efficiency while minimizing energy consumption.

- Corrosion Resistance: With options like stainless steel wheels, corrosion is effectively mitigated, making them perfect for cranes operating in corrosive or wet environments.

- Safety and Stability: When properly maintained, crane wheels contribute to the overall safety of lifting operations, reducing the risk of accidents by ensuring stable and predictable movement of the crane.

6. Tailored Overhead Crane Wheel Solutions

Understanding that every lifting operation is unique, KCICRANES offers customizable overhead crane wheels designed to meet the specific needs of our clients. Whether you require wheels for heavy-duty lifting or lighter applications, we provide bespoke solutions that match the precise demands of your operation.

7. How to Select the Right Overhead Crane Wheels

When selecting overhead crane wheels, several factors must be considered, such as:

- The weight of the loads to be lifted.

- Environmental conditions, including temperature, humidity, and exposure to corrosive elements.

- The type of crane and track system in use.

Our experts at KCICRANES can assist you in selecting the ideal wheels for your crane, ensuring they meet your operational requirements and contribute to the efficiency and safety of your lifting operations.

8. Why KCICRANES for Your Overhead Crane Wheels?

KCICRANES Machinery stands as a trusted name in the crane manufacturing industry, offering high-quality overhead crane wheels designed to withstand the most demanding conditions. Here’s why we’re the right choice for your crane wheel needs:

- Expertise: With extensive experience in crane component manufacturing, we have a deep understanding of the technicalities involved in designing high-performance crane wheels.

- Customization: We work closely with clients to provide bespoke wheel solutions tailored to meet specific operational requirements, ensuring that every aspect of the crane’s performance is optimized.

- Rigorous Quality Control: Every wheel is subjected to rigorous testing to ensure compliance with safety and performance standards, guaranteeing reliability and long-term functionality.

- Competitive Pricing: We offer high-quality products at competitive prices, ensuring that our clients receive the best value for their investment.

9. Reach Out for Customized Overhead Crane Wheels

If you need overhead crane wheels that deliver exceptional performance, durability, and safety, KCICRANES Machinery is here to help. Contact us today for inquiries or to request a quote. Our team is dedicated to providing solutions that meet your exact lifting requirements. Reach us at info@kcicranes.com for more details.

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com