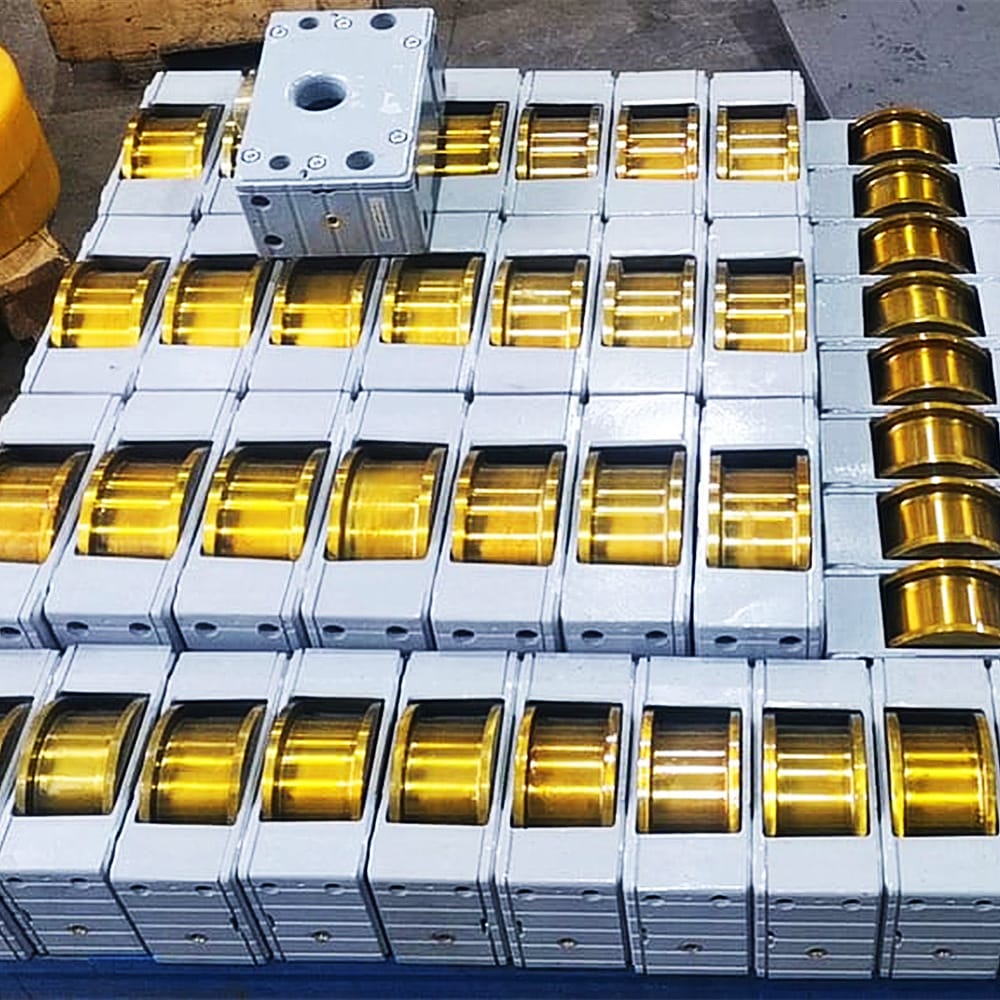

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

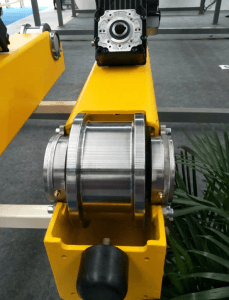

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

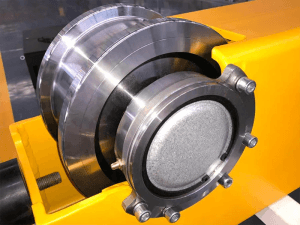

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

Crane Wheels

Introduction to Crane Wheels and Crane Wheel Boxes

Crane wheels and crane wheel boxes are essential components in the operation of cranes, serving a crucial role in facilitating the movement and stability of heavy loads. These components are meticulously designed and manufactured to withstand the demanding conditions of industrial settings.

Usage Scenarios:

Crane wheels and wheel boxes are commonly utilized in various industrial applications such as manufacturing plants, construction sites, warehouses, and shipyards. They are instrumental in enabling the smooth and efficient movement of heavy loads across different terrains.

Production Process:

The production of crane wheels and wheel boxes involves precision engineering and advanced manufacturing techniques. These components are typically forged or cast using high-quality materials to ensure durability and reliability under heavy loads and continuous usage.

Materials Used:

Crane wheels are often made from robust materials such as forged steel, cast iron, or specialized alloys to withstand the immense pressure and stress encountered during lifting operations. Similarly, crane wheel boxes are crafted from sturdy materials to provide structural support and ensure the proper alignment of the wheels within the crane system.

Simple Structure: Mechanical grabs have a comparatively simple structure, resulting in lower maintenance costs.

Wide Applicability: Suitable for general loading and unloading of materials like earth and stones.

Manual Operation: More manual operation is required compared to hydraulic grabs.

Lower force output: Mechanical grabs may have lower force output compared to hydraulic grabs, suitable for general loading and unloading tasks.

Considering the operational requirements and budget constraints, choosing between a hydraulic grab and a mechanical grab depends on their respective advantages and suitable applications

Types of Crane Wheels:

Single Flange Wheels: These wheels have a flange on one side to guide the wheel along the track and prevent it from derailing.

Double Flange Wheels: These wheels have flanges on both sides to provide added stability and prevent lateral movement on the track.

Flat Tread Wheels: These wheels have a flat tread surface and are suitable for use on smooth tracks where lateral stability is not a primary concern.

Grooved Wheels: These wheels have a groove in the tread surface to accommodate a V-groove track, providing precise alignment and reducing the risk of derailment.

Types of Crane Wheel Boxes:

Fixed Wheel Boxes: These wheel boxes have a fixed position and are commonly used in straightforward crane systems.

Adjustable Wheel Boxes: These wheel boxes allow for adjustments to be made to the wheel position, alignment, or height, providing flexibility in crane operation.

Swivel Wheel Boxes: These wheel boxes have a swivel mechanism that allows the wheels to rotate, enabling easier maneuverability and turning of the crane.

Spring-loaded Wheel Boxes: These wheel boxes are equipped with spring mechanisms to absorb shocks and vibrations, enhancing the smooth movement of the crane.

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com