| Parameter | Range |

| Voltage Rating | 220V-450V |

| Installation Type | Indoor/Outdoor |

| Length | 3m-5000m, customizable |

| Applications | Industrial cranes |

| Operating Temperature | -20°C to 60°C |

| Material | High-strength Steel |

| Control Type | Manual, Remote, or Automatic |

Crane Busbar: Essential Guide to Efficient Overhead Crane and Gantry Crane Power Systems

Crane Busbar: Essential Guide to Efficient Overhead Crane Power Systems

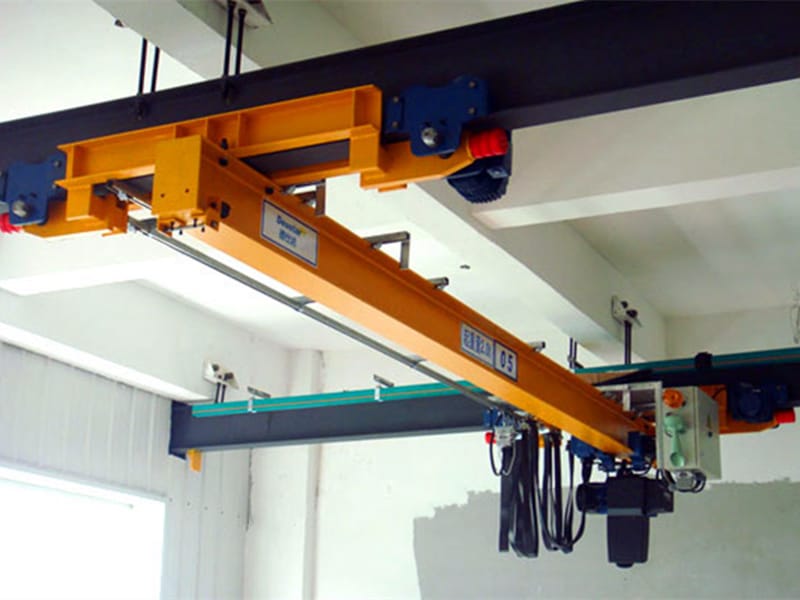

Overhead cranes rely heavily on reliable power distribution systems, with crane busbars playing a crucial role. These electrical components ensure that cranes receive consistent and safe power. In this article, we’ll explore the basics of crane busbars, the different types available, and the benefits they bring to industrial operations.

What is a Crane Busbar?

A crane busbar is an electrical component designed to deliver power to crane systems efficiently and securely. Unlike traditional wiring, a busbar system consists of rigid bars, often made of copper or aluminum, that conduct electricity over short distances. This setup enables smooth energy distribution, reducing the risks associated with loose wiring, overheating, and power surges.

Types of Crane Busbars

Crane busbars come in several types, each suited for specific environments and crane applications. Let’s explore some of the most common options available:

1. Enclosed Conductor Bars

Enclosed conductor bars are one of the most popular options for crane busbars. These systems house conductive bars within a protective enclosure, safeguarding them from external elements like dust, moisture, and mechanical impact. Enclosed conductor bars are ideal for heavy-duty applications where exposure to environmental hazards could compromise safety and performance.

2. Insulated Conductor Rails

Insulated conductor rails incorporate a layer of insulation around the conductive bar. This design helps to prevent accidental contact with electrical components, enhancing safety. Insulated conductor rails are often used in areas with high safety requirements, including manufacturing plants and warehouses with high traffic or operator movement.

3. Open Conductor Systems

Open conductor systems are commonly used in outdoor crane applications where weatherproofing may not be as critical. These busbars are exposed to the environment, making them suitable for cranes operating in less hazardous conditions. They are easier to maintain and inspect, making them a cost-effective solution in certain industries.

4. Festoon Systems

Festoon systems use a series of flexible, retractable cables to deliver power to cranes. While not technically a busbar, festoon systems are often grouped in similar categories due to their role in power delivery. Festoon systems are highly adaptable and are best suited for applications that require a high degree of movement.

Advantages of Crane Busbars in Power Distribution

Implementing crane busbars in industrial power systems offers multiple benefits, including enhanced efficiency and safety. Here’s how busbars optimize crane operations:

1. Improved Safety

Busbars provide a streamlined way to deliver power, reducing the need for tangled cables that can lead to accidents. Enclosed and insulated busbar systems minimize the risks of electrical hazards, ensuring operators and machinery are protected from contact with high-voltage currents.

2. Enhanced Durability

Built to withstand industrial environments, crane busbars are typically made from robust materials like copper or aluminum. This durability helps them resist wear and tear, ensuring they last longer than standard wiring systems. Moreover, enclosed designs offer added protection from elements that might otherwise degrade components over time.

3. Simplified Maintenance

Compared to conventional wiring, busbars are far easier to maintain. Open conductor systems, for example, allow for quick visual inspections and repairs. Enclosed conductor systems require minimal maintenance and protect components from dirt, debris, and moisture, reducing the frequency and complexity of maintenance tasks.

4. Efficient Power Distribution

Busbars provide efficient energy transfer with minimal power loss. By reducing resistance, they ensure that cranes receive a steady supply of power, which is vital for smooth operations. Busbars can handle high current loads without overheating, making them ideal for heavy-duty applications.

Selecting the Right Crane Busbar System

Choosing the best crane busbar depends on several factors, including the operating environment, load requirements, and safety considerations. When selecting a busbar system, consider the following:

1. Environmental Conditions

Indoor and outdoor crane operations require different types of busbars. For indoor settings, enclosed or insulated systems provide the necessary protection. Outdoor applications may benefit from open conductor systems, especially if maintenance access is a priority.

2. Load Requirements

The amount of power your crane requires will affect the type of busbar you need. Heavy-duty applications might need high-capacity busbars that can handle large current loads, while lighter applications may suffice with smaller systems.

3. Installation and Maintenance Needs

Busbar installation should be straightforward to ensure minimal downtime. Choosing a system that aligns with your maintenance capabilities will save time and costs over the long term. Some systems, like festoon, are more flexible and easy to install but may require more frequent inspections.

Conclusion

Crane busbars are an essential component for powering overhead crane systems efficiently and safely. By understanding the various types and advantages of busbars, businesses can optimize their crane operations for better performance and reliability.

If you need any other crane kits,welcome to send a free inquiry.Email:info@kcicranes.com

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com