| Parameter | Range |

| Load Capacity | 500kg-120 Tons |

| Weight | 50-800kg/pcs |

| Wheel Diameter | 400 mm to 1200 mm, customizable |

| Wheel Width | 200 mm to 500 mm,customizable |

| Operating Temperature | -20°C to 60°C |

| Material | High-strength Steel |

| Control Type | Manual, Remote, or Automatic |

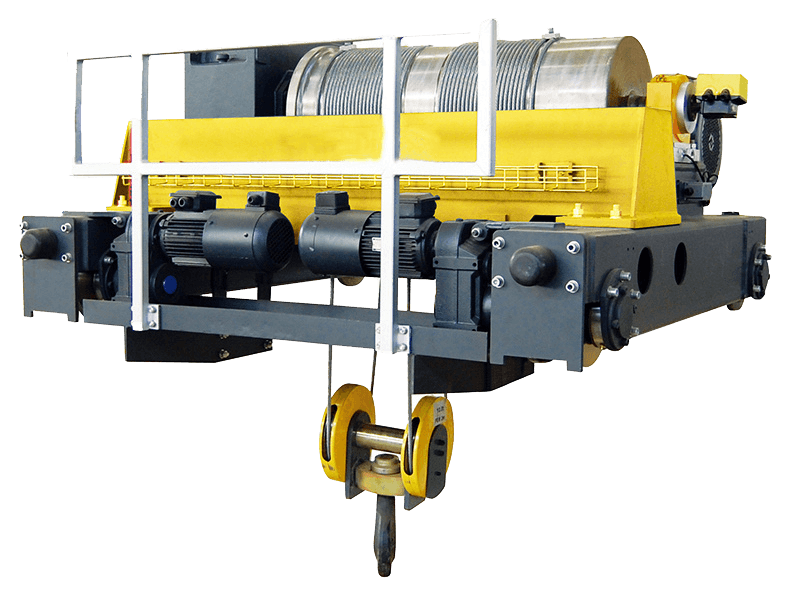

DRS Wheel Block System

Introduction: What is the Drs Wheel Block System?

The Drs Wheel Block System is a highly reliable solution designed to enhance the functionality and safety of industrial equipment. This system, commonly utilized in material handling, cranes, and automated systems, provides exceptional load-bearing capabilities. From factories to ports, this system is key in improving operational efficiency and minimizing safety risks.

As industries strive to improve their processes, systems like the Wheel Block System are becoming crucial components in reducing downtime, enhancing worker safety, and boosting productivity. In this article, we’ll cover the following key aspects:

- The core functionality of the Drs Wheel Block System.

- Benefits and applications.

- How to choose the right system for your operations.

- FAQs and a final conclusion.

How Does the Drs Wheel Block System Work?

The Drs Wheel Block System operates as a foundational component for machinery like overhead cranes and conveyor systems. At its core, it is a modular wheel block that allows for the secure movement of large loads across long distances. By offering a range of designs, this system provides flexibility in load handling, with variations in wheel diameter and material types to suit different industrial environments.

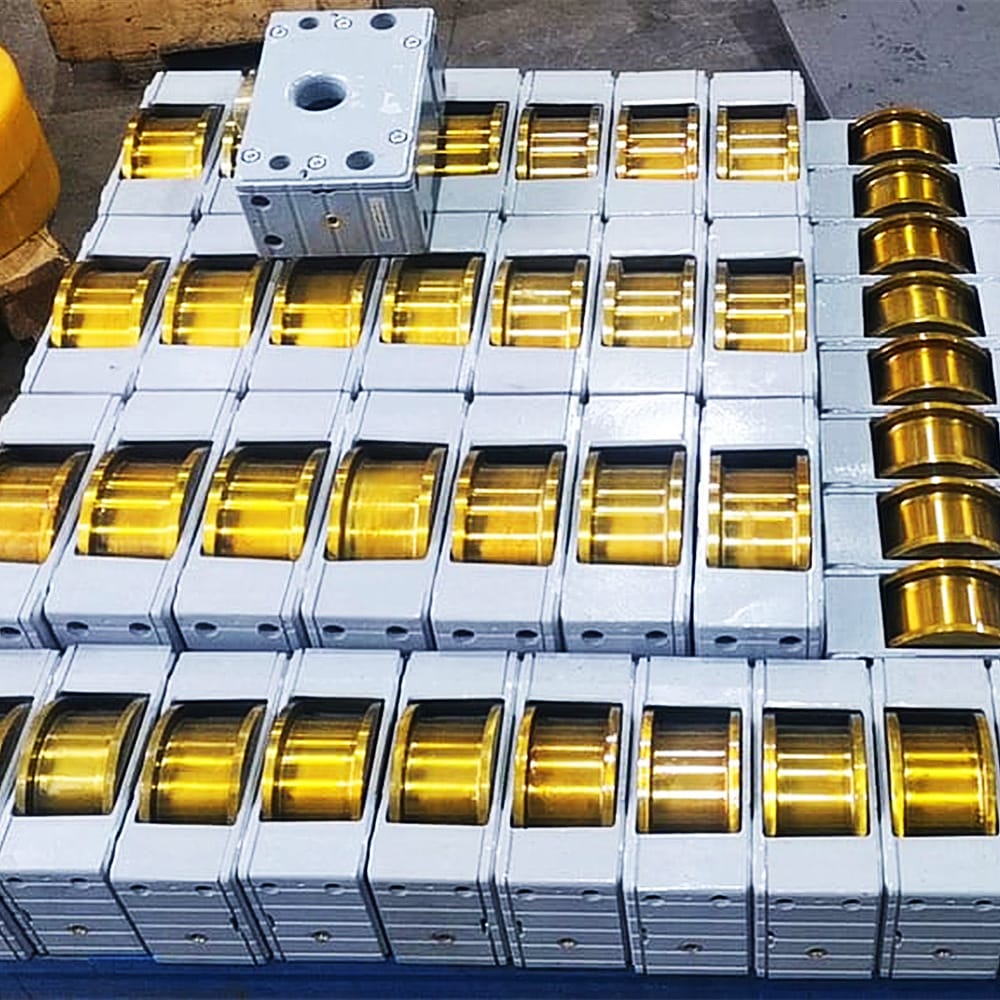

Key components include:

- Housing Units: The system’s robust housings protect the wheel components from external damage and corrosion.

- Wheel Blocks: The wheels, typically made from steel or polyurethane, provide high resistance to wear and tear, ensuring a long lifespan.

- Bearings: Bearings within the system provide smooth rotation and ensure that the wheels operate efficiently with minimal friction.

- Mounting Options: The system offers various mounting configurations, including direct mounting to machinery, enhancing versatility.

Benefits of the Drs Wheel Block System

It is known for several advantages that make it a preferred choice in industrial applications:

1. Load Capacity

These systems are engineered to handle extreme loads, with some models supporting over 10 tons. This makes them ideal for heavy industrial tasks like crane operations and material transportation.

2. Durability

Constructed from high-quality materials, the wheel blocks resist wear and damage, even in harsh conditions. This enhances the system’s lifespan and reduces the need for frequent replacements.

3. Versatility

Whether it’s for manual or automated systems, the Drs Wheel Block System can be adapted to various machinery setups. The system’s modular design makes it compatible with different equipment configurations.

4. Improved Safety

With proper installation and maintenance, the Drs Wheel Block System enhances safety by providing stable load handling and minimizing risks associated with equipment failures.

5. Energy Efficiency

By ensuring smooth and consistent movement of loads, the system helps reduce energy consumption. This not only reduces operational costs but also supports sustainability goals in industrial settings.

Applications of the Wheel Block System

1. Overhead Cranes

One of the most common uses of the Drs Wheel Block System is in overhead cranes, where precision and stability are paramount. The system ensures smooth horizontal movement of the crane across beams.

2. Conveyor Systems

The modular nature of the system makes it suitable for conveyor belts and other material handling equipment that require consistent movement.

3. Automated Guided Vehicles (AGVs)

In automated systems, such as AGVs used in warehouses or factories, the wheel block system offers the reliability needed for autonomous movement and load management.

4. Factory Equipment

The system is also integrated into various types of factory machinery, improving the overall efficiency of manufacturing processes.

Choosing the Right Wheel Block for Your Needs

1. Load Requirements

Understand the maximum load your system will need to handle. Choose a system that exceeds these requirements for added safety.

2. Environmental Conditions

For environments exposed to harsh weather or chemicals, opt for wheel blocks with corrosion-resistant materials like stainless steel or polyurethane coatings.

3. System Compatibility

Ensure that your wheel block system is compatible with your existing machinery. Consult the manufacturer for specific guidelines on installation and use.

4. Maintenance

Choose a system that offers easy maintenance access. Regular checks and part replacements will keep your equipment running smoothly and safely.

Frequently Asked Questions (FAQs)

1. What is the maximum load capacity of the Drs Wheel Block System?

Depending on the design, the load capacity varies by model but can support up to 100 tons or more.

2. Can the system operate in harsh conditions?

Yes, the Drs Wheel Block System is built to withstand harsh environmental conditions, such as extreme temperatures or chemical exposure, with the appropriate material selection.

3. How long does the system last?

With proper maintenance, the Wheel Block System can last several years, depending on usage intensity and environmental factors.

4. Is the system easy to install?

Yes, the system is designed for straightforward installation, with modular components that fit seamlessly into existing machinery setups.

5. Does the system require frequent maintenance?

Maintenance intervals vary, but regular inspections are recommended to ensure optimal performance and to address wear and tear.

KCICRANES Crane Kits

The Drs Wheel Block System plays a critical role in ensuring the smooth, efficient, and safe operation of various industrial machinery. Its ability to handle heavy loads, its adaptability to different environments, and its contribution to energy efficiency make it a top choice for industries worldwide. Whether you are operating an overhead crane, a conveyor system, or automated machinery, investing in the Drs Wheel Block System is a sound decision for enhancing operational productivity and safety.

If you need any other crane kits,welcome to send a free inquiry.Email:info@kcicranes.com

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com