KCICRANES-Professional Crane Kits Supplier

In industrial crane systems, the end carriage wheel is one of the most critical components ensuring smooth and reliable operation. As cranes are used to move heavy loads with precision, the end carriage wheels play a pivotal role in facilitating safe, efficient movement across tracks. For industries that rely on cranes for material handling, selecting high-quality end carriage wheels can drastically improve performance and reduce downtime. At KCICRANES Machinery, we specialize in manufacturing end carriage wheels, overhead cranes, portable gantry cranes, crane wheels, and other essential crane components.

In this article, we’ll explore the importance of end carriage wheels and how KCICRANES delivers superior solutions for industrial operations.

We specialize in high-quality crane solutions at KCICRANES Machinery, a leading crane and crane parts manufacturer in China. For inquiries, contact us at info@kcicranes.com.

What is an End Carriage Wheel?

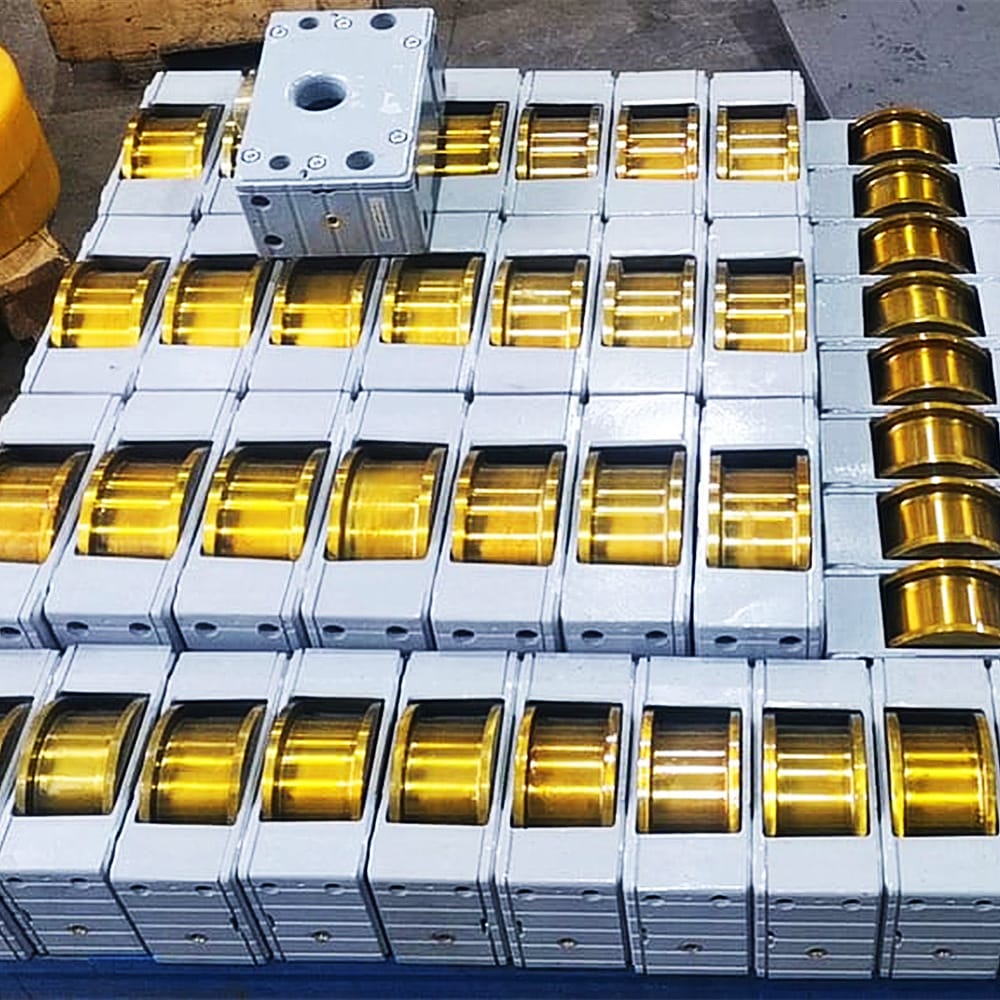

The end carriage wheel is an integral part of an overhead crane or gantry crane system. It is installed on the crane’s end carriage and allows for the crane’s movement along a track or runway. The wheels are designed to support the load of the crane and enable its travel along the beams or rail systems. These wheels bear a significant amount of weight and are subjected to constant stress as cranes carry and move heavy materials.

End carriage wheels are typically made from durable materials like steel or cast iron, designed to withstand the heavy-duty demands of industrial environments. Their performance is crucial for the smooth operation of the crane, which is why high-quality manufacturing is essential.

Importance of End Carriage Wheels in Crane Systems

End carriage wheels offer a range of benefits in crane systems, including:

1. Smooth and Reliable Movement

End carriage wheels enable smooth travel across the crane’s tracks, minimizing friction and reducing wear and tear on other components. This ensures that the crane can operate efficiently, even in high-demand environments, contributing to less downtime and maintenance.

2. Enhanced Safety

The stability of end carriage wheels is directly linked to the safety of crane operations. High-quality wheels prevent unnecessary vibration or instability, which could lead to accidents or operational inefficiencies. This is especially important when lifting heavy loads, where precision and control are paramount.

3. Load Bearing Capacity

End carriage wheels bear the weight of the crane and its load, making their durability crucial for the crane’s performance. These wheels must be engineered to handle heavy and dynamic loads consistently. KCICRANES ensures that our end carriage wheels are designed to meet these rigorous demands.

4. Extended Lifespan

Durability is a key feature of well-designed end carriage wheels. Regular replacement of low-quality wheels can result in operational disruptions. By using premium materials and advanced manufacturing techniques, we guarantee that our wheels provide long-lasting performance, saving on replacement costs and downtime.

Types of End Carriage Wheels

The design and functionality of end carriage wheels can vary based on the specific needs of the crane system. Here are some common types of end carriage wheels:

1. Standard End Carriage Wheels

Standard end carriage wheels are commonly used in overhead cranes, hoists, and other material handling systems. These wheels are typically designed to handle average load capacities and standard operational conditions.

2. Heavy-Duty End Carriage Wheels

Heavy-duty end carriage wheels are built for industrial applications where higher load capacities and greater resistance to wear and tear are required. These wheels are designed to carry loads ranging from several tons to more than 100 tons.

3. Corrosion-Resistant End Carriage Wheels

In industries where exposure to harsh environments is common (such as chemical plants or outdoor construction sites), corrosion-resistant end carriage wheels are crucial. These wheels are made from special materials or coated with protective layers to prevent rust and extend their lifespan.

4. Custom End Carriage Wheels

Some applications require custom end carriage wheels that cater to unique requirements. Whether it’s for specialized cranes, tight spaces, or unique load-bearing capacities, KCICRANES offers custom-made solutions to ensure that every crane operates at peak efficiency.

Why Choose KCICRANES for End Carriage Wheels?

At KCICRANES Machinery, we understand the importance of reliable, high-performance end carriage wheels in crane systems. As a leading crane and crane components supplier in China, we offer a range of high-quality products designed to meet the needs of industries worldwide.

Here’s why we are the preferred choice for end carriage wheels and other crane components:

1. Industry Expertise

With years of experience in manufacturing industrial cranes and crane components, KCICRANES has developed an in-depth understanding of the challenges faced by crane operators. Our expert team ensures that every end carriage wheel is designed with precision, efficiency, and durability in mind.

2. High-Quality Manufacturing

Our end carriage wheels are crafted using the finest materials and advanced manufacturing techniques. Whether you need standard, heavy-duty, or custom wheels, we ensure that each product meets international quality standards for performance and reliability.

3. Wide Range of Crane Components

KCICRANES provides a comprehensive range of crane components beyond end carriage wheels, including overhead cranes, portable gantry cranes, crane trolleys, transfer carts, busbars, and more. We can supply all your crane system needs, making us a one-stop shop for all your industrial lifting equipment.

4. Customization Options

We understand that every industrial application has unique requirements. KCICRANES offers customization options for end carriage wheels, ensuring that your crane system performs optimally, no matter the size or complexity of your project.

5. Global Reach and Support

We serve clients worldwide, offering timely delivery and exceptional customer service. Whether you’re in need of a single replacement part or a complete crane system, KCICRANES is committed to providing the best solutions for your business.

Applications of End Carriage Wheels in Various Industries

End carriage wheels are used in a variety of industries, including:

1. Construction

In construction, cranes are used to lift heavy materials, machinery, and equipment. End carriage wheels are essential for maintaining the crane’s movement along construction sites, ensuring fast and efficient material handling.

2. Manufacturing

Manufacturers rely on overhead cranes to move heavy loads, materials, and products along assembly lines. The durability and smooth operation of end carriage wheels are vital for maintaining continuous production without interruptions.

3. Shipping and Logistics

In shipping yards and ports, cranes are used to load and unload containers from ships. End carriage wheels play a key role in enabling the cranes to move across long tracks quickly and efficiently, handling large, heavy containers.

4. Mining and Heavy Industries

In industries such as mining, heavy-duty cranes are used to transport raw materials, machinery, and tools. The end carriage wheels in these cranes are specially designed to handle the extreme loads and challenging environments typical of mining operations.

| Parameter | Range |

| Wheel Materials | 42CrMo,60Mn,65Mn,55#,60#,ZG340-640 .etc |

| Manufacturing Process | Forging,Casting,Rollmilling .etc |

| Wheel Diameter/mm | 200,250,315,400,500,630,710,800,1000 .etc |

| Wheel Gross Weight/kg | 82-87kg;133-163kg;200-262kg;284-405kg;605-1000kg .etc |

| Lifting Speed | 3 to 12 m/min |

| General bearing force | 8-104 Tons |

| Applications | Overhead cranes,gantry cranes,transfer carts,trains.etc |

| Parameter | Range |

| Loading Capacity | 2 to 100 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| DRS gearbox | Drive Reduction System |

| Drive Control | Allows for precise control of the crane’s movement speed and direction |

| Durability | Typically made from high-strength materials to withstand harsh working environments. |

| Control Method | Remote control, Pendant control, or Cabin control |

| Parameter | Range |

| Lifting Capacity | 250kg to 120 tons |

| Wheel Diameter | Φ200mm-Φ800mm |

| Wheel Gross Weight/kg | 80-500kg |

| Thickness | Typically range from 50 mm to 200 mm |

| Wheel Type | Solid wheels, grooved wheels, flanged wheels.etc |

| Operating Temperature | From -20°C to +100°C |

| Materials | Stainless steel, alloy steel, and cast iron.etc |

The end carriage wheel is more than just a small part of the crane system—it is a crucial component that contributes to the overall safety, reliability, and performance of the crane. By choosing high-quality wheels from trusted suppliers like KCICRANES, you can ensure that your crane operates smoothly and efficiently, minimizing downtime and enhancing productivity. With our experience, quality manufacturing, and customer-first approach, KCICRANES is your ideal partner for all your crane and crane component needs.

Contact KCICRANES for End Carriage Wheels and More

At KCICRANES, we are dedicated to providing high-quality crane components that ensure safety, efficiency, and longevity for all types of industrial crane systems. Whether you’re looking for end carriage wheels, overhead cranes, gantry cranes, or other crane components, our team is ready to help you find the best solution for your needs.

For more information or a free inquiry, contact us at info@kcicranes.com. Let us help you take your crane operations to the next level with our premium products and expert services.

Address

Xinxiang City, Henan Province, China

Phone & Whatsapp

+86 16650373589

info@kcicranes.com